Pneumatic seed drill for cereals combined with disc harrow

OPERA 600 is the new universal combined seed drill capable of enhancing daily productivity and performing 3 operations in a single pass. Equipped with a pressurised hopper with a capacity of 5,100 litres, it is suitable for large farms and contractors. Available in a single 6 m version with a maximum of 48 rows, it is designed for tractors with power ratings between 240 and 360 hp. By combining multiple operations in a single implement (soil cultivation, fertiliser incorporation and sowing), the OPERA 600 aims to maximise the effectiveness of field operations, reducing costs and contributing to a more sustainable future.

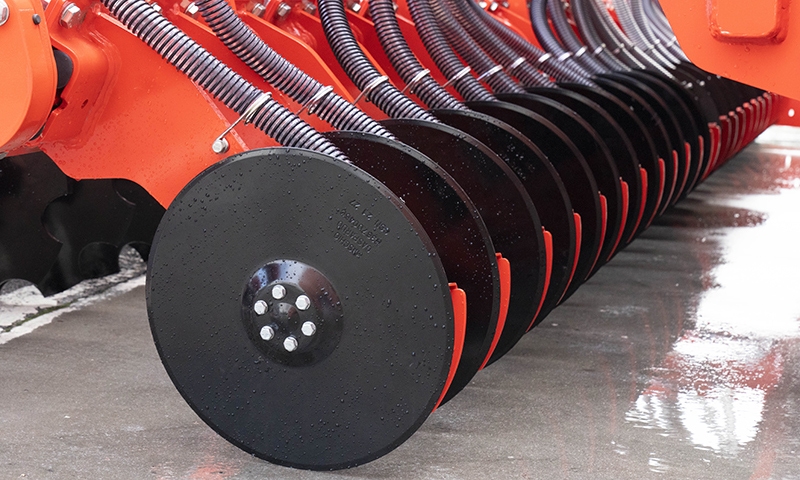

The machine is equipped with three independently adjustable working sections that combine six operations in a single pass. All working parts, from the discs for tilling the soil to the seed and fertiliser coulters, are equipped with independent arm connection elements with respective supports cushioned by 4 rubber silent blocks. This solution guarantees the greatest possible degree of movement of the working parts in order to operate efficiently even on uneven or unworked soil. The sturdy, semi-mounted chassis (optionally carried by means of an eye), with folding side members and crossbars, makes it possible to reduce the overall dimensions from 6 to only 3 metres for road transport, and thanks to the long drawbar, both road transfers and headland turns are made easy.

The new pressurised hopper features a high capacity of 5,100 l and has the possibility of varying the internal partition (60/40 or 50/50). This modulation allows for the best possible operation by combining different varieties, crops or fertilisers. Pressurisation is a technology already adopted in other MASCHIO GASPARDO seed drills, which improves the efficiency of product distribution along the entire working face and reduces the effort required by the hydraulically driven impeller, even in hilly areas. A solution that reduces the power required and consequently consumption and emissions.

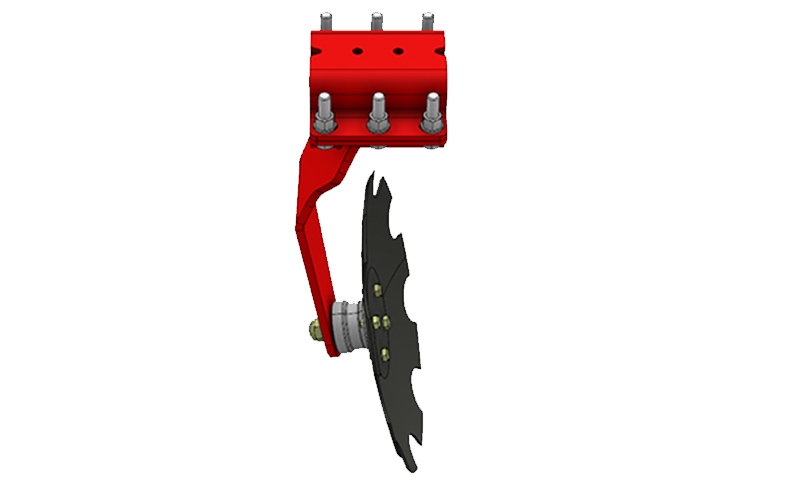

The newly developed X-FORCE seeding bar ensures a constant seeding depth even when working at high speeds and is capable of applying a ground pressure of up to 140 kg. The system consists of a double disc coulter with the same diameter as the fertiliser coulter (380 mm) and, thanks to its special V-shaped design, always ensures a uniform seeding depth even on heavy soils. The double-disc furrow opener has a mud scraper inside the V, which, together with the rear depth wheel made of soft self-cleaning rubber, makes it possible to work effectively even on wet soils, avoiding mud accumulations that could compromise correct deposition.

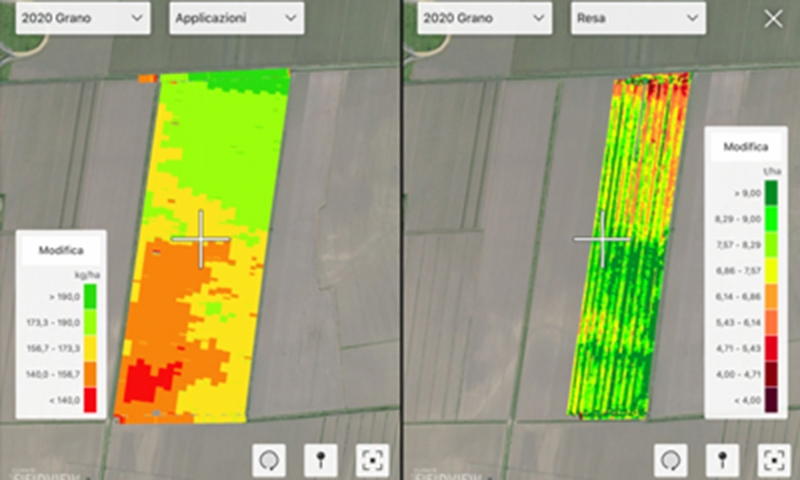

ISOTRONIC's electric drive with ISOBUS communication protocol allows digital control of the seed drill and all Precision Farming functions, simplifying calibration procedures for seed and fertiliser. Sensors and actuators help improve the operator's experience, allowing them to work more efficiently, saving time, effort and money.

The ability to perform multiple operations in a single pass not only saves time and allows you to work within tighter timeframes, but also reduces fuel consumption and equipment wear. All this translates into greater efficiency, savings and sustainability, which are increasingly necessary due to climate change. A highly versatile and productive, latest-generation machine.

| Measure | Working width (min) | Transport width | Hopper capacity | N. of rows | Inter-row (min) | Transmission | Depth wheel | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 600/48 | 6 m | 3 m | 5,100 lt | 48 | 12.5 cm | Electric | 330x50 | 177 kW | 10,240 kg |

| Measure | Working width (min) | Transport width | Hopper capacity | N. of rows | Inter-row (min) | Transmission | Depth wheel | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 600/48 | 6 m | 3 m | 5,100 lt | 48 | 12.5 cm | Electric | 330x50 | 177 kW | 10,808 kg |

| Measure | Working width (min) | Transport width | Hopper capacity | N. of rows | Inter-row (min) | Transmission | Depth wheel | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 600/48 | 6 m | 3 m | 5,100 lt | 48 | 12.5 cm | Electric | 330x50 | 177 kW | 10,240 kg |

| Measure | Working width (min) | Transport width | Hopper capacity | N. of rows | Inter-row (min) | Transmission | Depth wheel | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 600/48 | 6 m | 3 m | 5,100 lt | 48 | 12.5 cm | Electric | 330x50 | 179 kW | 10,552 kg |

Two-point hitch III^ cat. ISO, III^ cat. ASAE

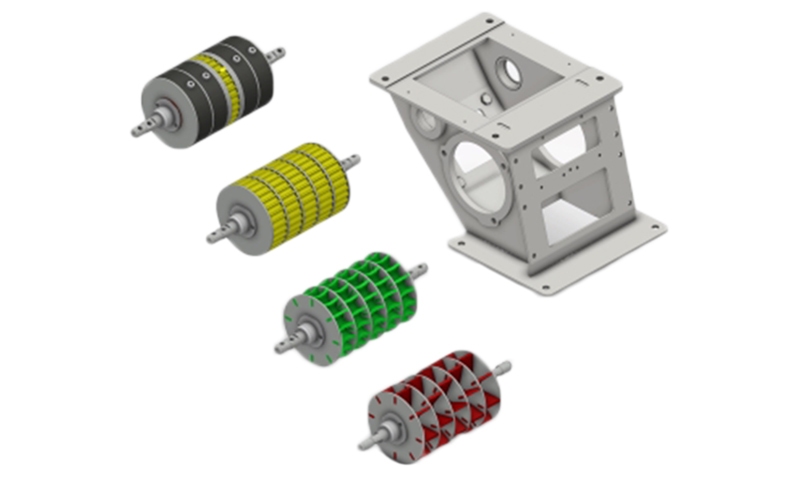

2 centralized volumetric doser for seed and fertilizer

Complies with ISO 11783 standard

ISOBUS GENIUS MASTER system

GPS speed sensor

Seed pneumatic distribution with tractor dependent fan drive

Pressurized pneumatic transport system

5100 liter hopper: two adjustable compartments 60% – 40% or 50% – 50% seed/fertilizer

Metering rollers G1000, F25-125 and N500

Tractor dependent electrical power supply system

Containment side deflectors

Electronic scale with calibration and emptying tray

12 wheel 425/55 R17 tire roller with 125/250mm offset

2 ranks of Ø 460 mm independent toothed discs silent block cushioned

Hydraulic disc cultivator depth regulation

Diverter valve underneath each doser

Seeding elements with 3D suspension on silentblocks, arranged in two ranks

Mechanical seed depth adjustment (Clip limiters on cylinders)

Wide vertical disc coulter excursion

Center distance between seeding ranks 150 mm

Staggered double disc seed spreaders (Ø380 mm) with 4 point bearings

Self-adjusting internal polyurethane and wear-resistant steel scraper on double disc

Seeding units with polyurethane seed conveyor

Three point adjustable seed covering harrow

Electrohydraulic seed unit pressure regulation 84-143 kg

Fertilizing elements with 3D suspension on silentblocks, arranged on a single rank

Single disc fertilizer spreaders (Ø380 mm) with 4 point bearings

Hydraulic adjustment of fertilizer depth

Interior lighting of the hopper

Rear LED work lights

Sequence of automatic end of field tool handling