Variable chamber round baler with electronic variable geometry and 4 belts

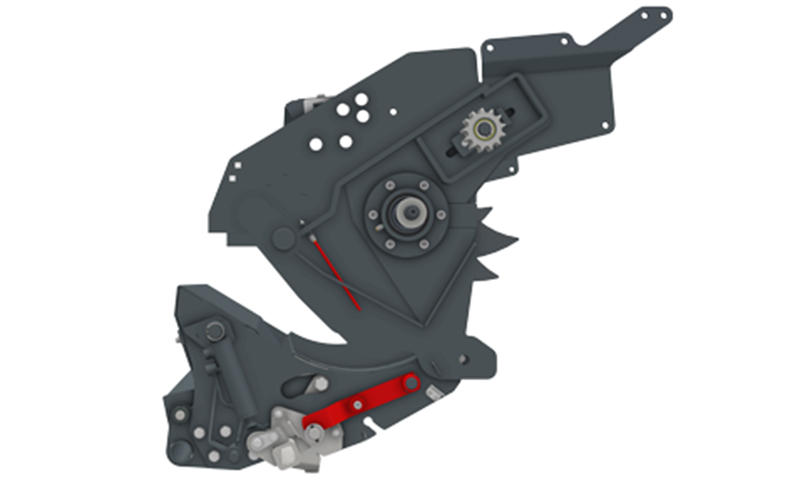

EXTREME 3 is the round baler with variable chamber and geometry, synthesis of high performances and maximum attention to product collection. The double rocker arm system, for the variable chamber and geometry management, with pressure up to 210 bar, allows to collect any type of product and level of humidity, for optimal storage.

Exceptional durability, great working capacities, perfectly formed, compact and heavy bales up to 165 cm diameter make EXTREME 3 a profitable investment, also thanks to the possibility of setting it up with 4 feeding systems.

The variable chamber management is made possible by a double rocker arm controlled by hydraulic cylinders. The first defines the pressure and the diameter of the bale with the possibility of creating a pre-chamber with zero pressure up to 90 cm, while the second rocker automatically compensates the tension of the four ENDLESS clinched belts during the formation of the bale. This allows to obtain enormous advantages for those who are attentive to the product quality.

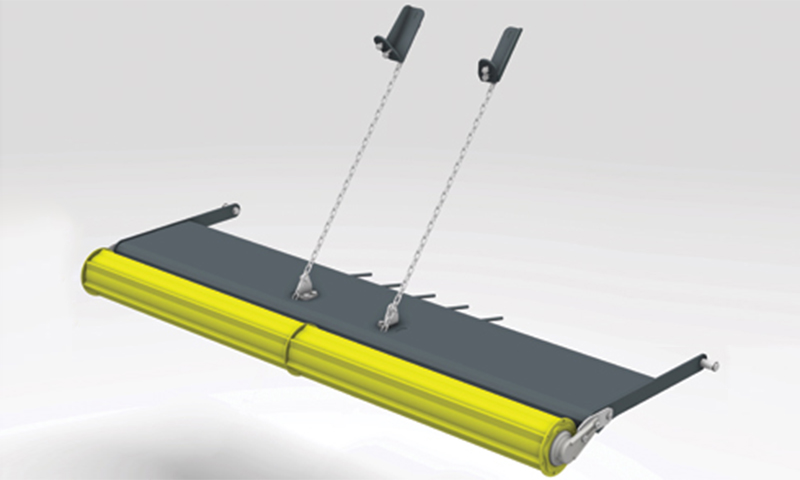

The large 220 cm pick-up with pivoting wheels allows to operate even in the presence of not perfectly regular and abundant windrows. The harvest of the product is delicate with any type of forage, even in the case of leafy product. The machine is standard equipped with a windrow press roller.

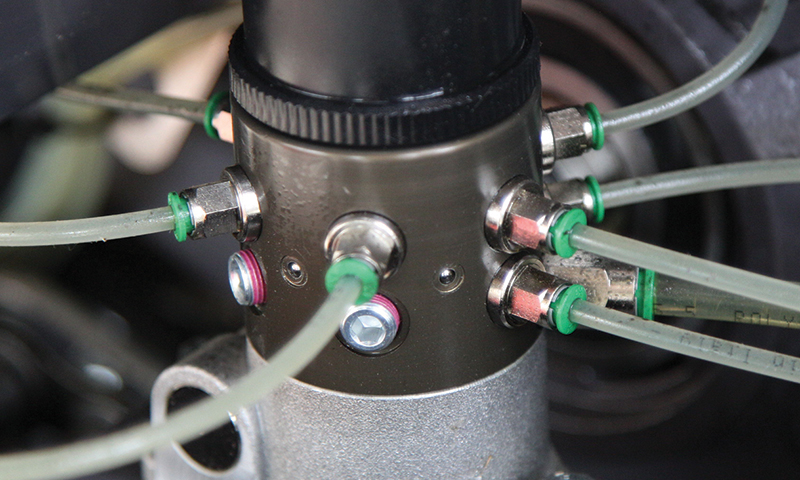

To respond to the various needs of contractors who stress machines for long time, EXTREME 3 is equipped with 1 ”¼ reinforced chains capable of withstanding the heaviest stresses. The automatic chain oiling system ensures a machine that is always well greased and performing.

EXTREME series 3 is versatile, in fact there are 3 feeding systems that can be requested: HTR rotary feeder, HTC rotary feeder with 15 knives and HTU rotary feeder with 25 knives. The stars of all rotors are made of high strength HARDOX, to minimise wear during work.

Designed for true professionals, EXTREME 3 is equipped with 4 ENDLESS belts, thanks to which optimal resistance is ensured in any condition, even at high pressures and speeds. Covering the entire width of the bale during formation reduces product losses and preserves its quality. The two motorized rollers ensure perfect rotation of the belts even in the case of very wet product.

To increase productivity on field and reduce possible downtime, EXTREME 3 has been designed with a drop floor. This system, which temporarily increases the size of the machine's inlet, allows to quickly solve any blockages due to excess product, facilitating the work of the operator who can manage and solve the problem from tractor cab.

Designed for true professionals, EXTREME 3 combines robustness and high pressing performance—up to 210 bar—in a single machine. The variable chamber, which can also create a zero-pressure pre-chamber, allows for the collection of different types of material with varying moisture levels, always ensuring optimal results. The ENDLESS belts contribute to a long working life for this machine.

| Measure | Ø bale (min) | Ø bale (max) | Bale width | Pick-up width | Belts type | No. of belts | Tying | Wheels | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 365 HTR | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 70 kW | 3,470 kg |

| Measure | Ø bale (min) | Ø bale (max) | Bale width | Pick-up width | Belts type | No. of belts | Tying | Wheels | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 365 HTC | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 79 kW | 3,550 kg |

| Measure | Ø bale (min) | Ø bale (max) | Bale width | Pick-up width | Belts type | No. of belts | Tying | Wheels | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 365 HTU | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 79 kW | 3,657 kg |

TRANSMISSION

Wide angle cam-shaft

PTO 540 rpm

CONTROL GROUP

Multifunction electronic control unit ICON

FEEDING SYSTEM

Pick-up 220 cm with 4 tooth bars with fixed wheels and crop roller

Rotor TOPCUT: 15 knives, cutting length 77 mm (version HTC)

Rotor (version HTR)

Rotor ULTRACUT: 25 knives, cutting length 45 mm (version HTU)

Drop floor

BALE COMPRESSION SYSTEM

Variable chamber with pre-starting chamber

Electronic variable geometry

Hydraulic bale compression with electronic density adjustment

4 endless closed-loop belts with width 277 mm

TYING SYSTEM

Net tying system

Net stock compartment

LUBRIFICATION

Automatic chain and pick-up lubrication

Manual centralized greasing system

FRAME

Adjustable axle

Couple of shrinking cups

Pick-up support chains

Ladder

LED road lights

Tires 400/60-15,5

Mother Regulation road homologation available without braking system

| Measure | Ø bale (min) | Ø bale (max) | Bale width | Pick-up width | Belts type | No. of belts | Tying | Wheels | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 365 HTR | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 70 kW | 3,470 kg |

| Measure | Ø bale (min) | Ø bale (max) | Bale width | Pick-up width | Belts type | No. of belts | Tying | Wheels | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 365 HTC | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 79 kW | 3,550 kg |

| Measure | Ø bale (min) | Ø bale (max) | Bale width | Pick-up width | Belts type | No. of belts | Tying | Wheels | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 365 HTU | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 79 kW | 3,657 kg |

TRANSMISSION

Wide angle cam-shaft

PTO 540 rpm

CONTROL GROUP

Complies with ISO 11783 standard

FEEDING SYSTEM

Pick-up 220 cm with 4 tooth bars with fixed wheels and crop roller

Rotor TOPCUT: 15 knives, cutting length 77 mm (version HTC)

Rotor (version HTR)

Rotor ULTRACUT: 25 knives, cutting length 45 mm (version HTU)

Drop floor

BALE COMPRESSION SYSTEM

Variable chamber with pre-starting chamber

Electronic variable geometry

Hydraulic bale compression with electronic density adjustment

4 endless closed-loop belts with width 277 mm

TYING SYSTEM

Net tying system

Net stock compartment

LUBRIFICATION

Automatic chain and pick-up lubrication

Manual centralized greasing system

FRAME

Adjustable axle

Couple of shrinking cups

Pick-up support chains

Ladder

LED road lights

Tires 400/60-15,5

Mother Regulation road homologation available without braking system