Folding professional straw chopper

GEMELLA is a professional folding straw chopper designed both for the management of the more demanding crop residues (maize, rapeseed, sorghum, grass and sunflowers) and for the maintenance of uncultivated ground. It comes in two working widths - 4.65 m and 6.20 m - and is designed to work with tractors in the 120 - 300 and 150 - 300 HP range respectively.

The folding frame allows the implement to be folded to a width of 240 cm for road travel.

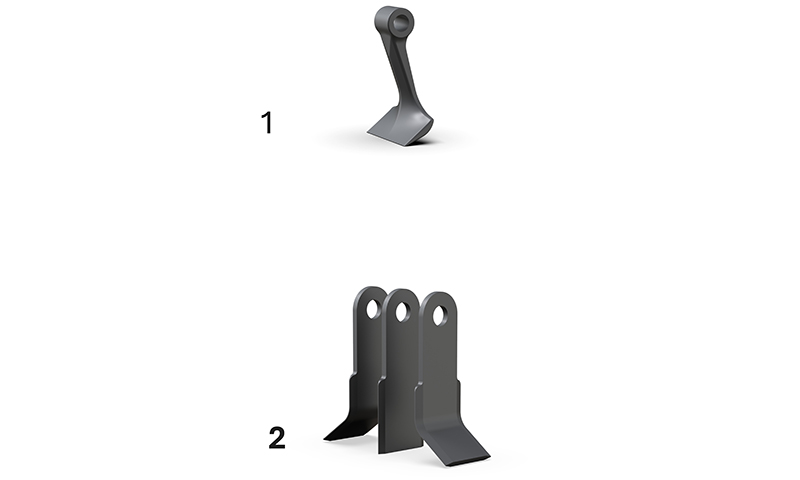

GEMELLA has a dual-wing folding frame. The side drive system employs 5 toothed belts that drive the electronically balanced rotors with tools (hammer flails or blades) mounted in a helical arrangement.

The extra strong rotor mounts are made of hot-formed steel and are mounted inside the end plate to protect the bearings. This makes the mulcher much stronger than competitors' versions featuring externally mounted covers. The HEAVY-DUTY bearings ensure unparalleled reliability and peace of mind. The special "barrel" race is designed to withstand punishing radial loads and knocks, offering unbeatable strength to handle with even the toughest jobs.

The wings' floating feature allows the implement to better follow the contours of the ground.

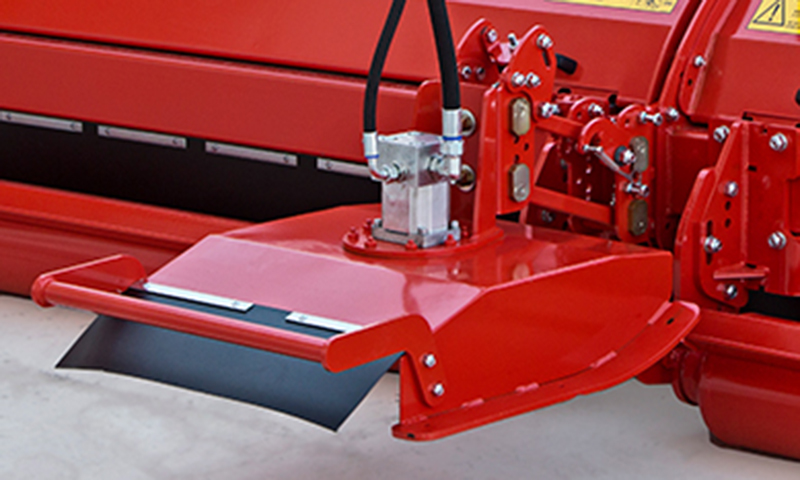

This new hydraulic twin-blade cutting device has been designed to be attached at the rear, ensuring full management of residue in the field, including the uncut strip that escapes GEMELLA's shredding heads. The resulting assembly is teamed with an oil cooling system that uses a fan unit. Available on request.

For a finer mulch, GEMELLA has the toothed lower counter blade mounted on the internal structure inside the hood. With this device, the residue is shredded further, which helps speed up the decomposition process.

Both models can be fitted with rear pivoting wheels to adjust work height and improve headland manoeuvrability. If these wheels are fitted, the rear roller must be removed.

| Measure | 3rd point | Working width (min) | Total width | Transport width | N. of tools | Power required HP | Power required KW | Weight |

|---|---|---|---|---|---|---|---|---|

| 470 | Rigid | 4.65 m | 5.02 m | 2.4 m | 48 | 118-296 hp | 88-221 kW | 2,500 kg |

| 620 | Rigid | 6.2 m | 6.57 m | 2.4 m | 64 | 148-296 hp | 110-221 kW | 2,900 kg |

| Measure | 3rd point | Working width (min) | Total width | Transport width | N. of tools | Power required HP | Power required KW | Weight |

|---|---|---|---|---|---|---|---|---|

| 470 | Rigid | 4.65 m | 5.02 m | 2.4 m | 144 | 118-296 hp | 88-221 kW | 2,500 kg |

| 620 | Rigid | 6.2 m | 6.57 m | 2.4 m | 192 | 148-296 hp | 110-221 kW | 3,020 kg |

TRACTOR CONNECTION

3 point hitch cat. I^, III^ and IV^N

Floating third point connection rod

TRANSMISSION

PTO shaft

PTO 1000 rpm with double transmission and integrated freewheel

Side direct shafts and oil-bath extensions

Side transmissions with 5 toothed belts

Transmission belts external adjustment

Quick PTO shaft protection removal

FRAME

Lower toothed counter-blade

Safety hydraulic locks for transport

Manual selection device for fix/upwards floating mode

Central divider and “L” shaped blades working close to the central flank to minimize the uncutted surface between the shredding heads

Rear bonnets openable for maintenance

Adjustable pair of skids

Road lights (disassembled)

ROTOR

Rotors with electronic balancing and helical arrangement of tools

Heavy duty barrel type bearings

Blades Kit "05"

REAR ROLLER

Adjustable rollers unit

SAFETY

Front safety flaps

Double standing support

«CE» protections