Trailed sprayer with hydraulic lifting

CAMPO 22-32 represents the segment of MASCHIO GASPARDO medium-sized trailed sprayers. Reliable and robust, it has been designed to meet the needs of any farmer always ensuring maximum efficiency and spraying precision, also with a view to environmental respect. CAMPO 22-32 is available with three hydraulic booms up to a max of 21 m with wheeled lifter for the “C” version and 28 m with parallelogram lifter for the “P” version. It features standard set-up that can be implemented with an extensive set of accessories for tailor-made equipment.

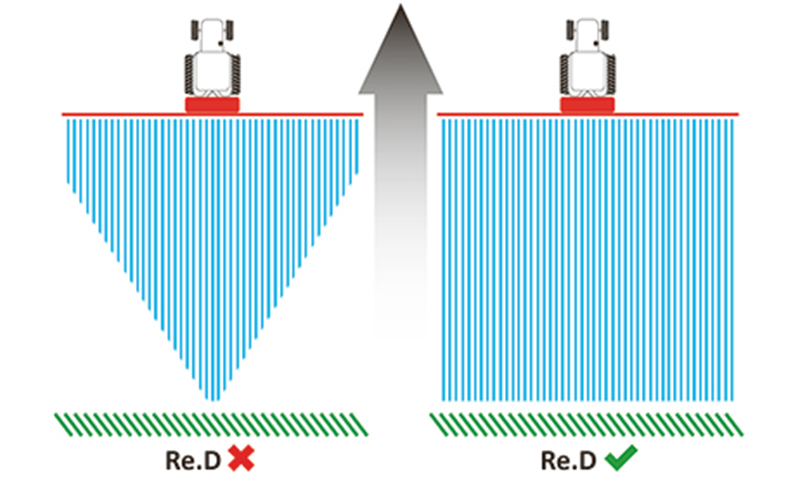

CAMPO 22-32 has been created with the intention of offering equipment that is easy to manage and maintain. Every detail, from the smallest to the largest, has been created to ensure maximum functionality. The manually-operated water panel mounted on the machine sums up all the equipment features, as well as the premixer and hand washing cistern near the valve controls to have everything at your fingertips. The high operational efficiency in the field is ensured by some essential systems. Deviokit is used to clean the water circuit even with the main tank full of product. Re.D recirculation system ensures maximum precision and distribution quality, eliminating possible delays in opening the sections, regardless of the boom length.

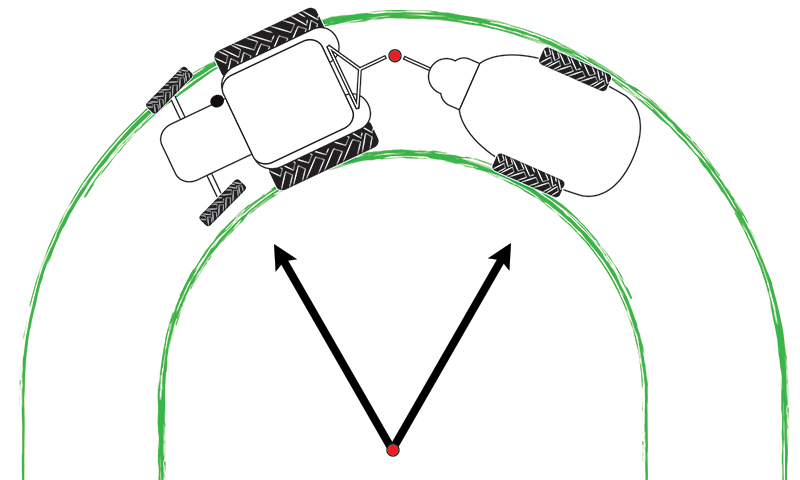

CAMPO 22-32 is characterised by the possibility of choosing the “C” wheeled type boom lifting system or the “P” parallelogram type which respectively allow a vertical excursion of 1 m and 1.5 m. The high reliability of the booms is ensured by the dynamic stress damping system through a double hydropneumatic shock absorber. The available WORK U (only for “C” version), ALA 500, 600 and 700 booms (the latter only for “P” version) can be controlled via the convenient centralised push button panel supplied with OILDRIVE system. Customisation also includes the air sleeve anti-drift system, the choice of braked axle, suspension axle and different types of drawbars to improve machine manoeuvrability during field operations.

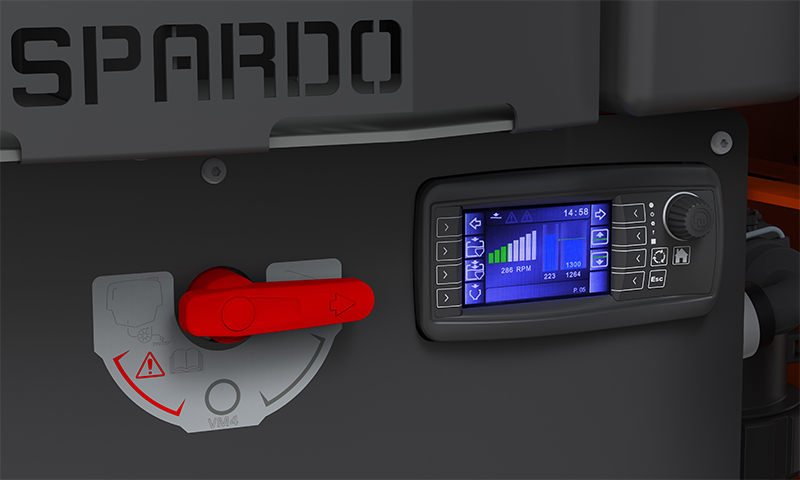

For the more demanding farmers and contractors there is also ISOTRONIC version with ISOBUS communication protocol, which matched with different Universal Terminals, allows the use of Precision Farming functions and the centralised control of all water and hydraulic functions.

ISOTRONIC version also makes it possible to use the electronically-controlled steering drawbar for the perfect overlap of the sprayer tracks on the tractor ones and the electronic control of the height of the boom from the crop.

| Measure | Real tank capacity | Boom width | N. of sections | Circuit rinse tank capacity | Pump type | Control group | Drawbar | Towing eye | Wheels | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 22C | 2,400 lt | 15 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,500 kg |

| 22C | 2,400 lt | 18 m | 7 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,500 kg |

| 32C | 3,200 lt | 15 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| 32C | 3,200 lt | 18 m | 7 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| Measure | Real tank capacity | Boom width | N. of sections | Circuit rinse tank capacity | Pump type | Control group | Drawbar | Towing eye | Wheels | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 22C | 2,400 lt | 16 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,500 kg |

| 22C | 2,400 lt | 18 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,250 kg |

| 22C | 2,400 lt | 21 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,500 kg |

| 32C | 3,200 lt | 16 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| 32C | 3,200 lt | 18 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,500 kg |

| 32C | 3,200 lt | 21 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,500 kg |

| Measure | Real tank capacity | Boom width | N. of sections | Circuit rinse tank capacity | Pump type | Control group | Drawbar | Towing eye | Wheels | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 22C | 2,400 lt | 18 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,500 kg |

| 22C | 2,400 lt | 21 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,500 kg |

| 32C | 3,200 lt | 18 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,500 kg |

| 32C | 3,200 lt | 21 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

FRAME

Cataphoresis painted frame with stepladder and platform

Square axle 80 mm with adjustable wheelbase and track (min1650 - max2250)

Mechanical parking foot

TANK GROUP

Facilitated emptying polyethylene tank

Hinged lid with bayonet joint

Washing circuit system with independent tank

2 circuit rinse rotating jets

Handwashing tank

Empty level

FILLING AND FILTERING

M-PANEL: manual panel on the left side with centralized controls

3 way deviator for tank filling

2" camlock quick hitch for filling from external non-pressurized source

Inspectionable external suction filter

External selfcleaning delivery filter

GreenMix T30 premixer with parallelogram

Double hydraulic agitator through perforated tube and pressure agitators

DEVIOKIT: circuit rinse system even with full tank

Flowback: advanced anti-drip system

PUMP

Comet pump

Pump flow control kit for functional testing

PTO shaft (tractor side yoke 1" 3/8 Z6)

CONTROL GROUP

Electronic DPAE adjustment

BRAVO 180 computer

Control panel for managing water and hydraulic functions

Speed sensor on the wheel

Flowmeter

Differential pressure gauge

BAR SUSPENSION

Trolley lifting system

Self-leveling pendulum frame with jacks, shock absorbers and springs

Hydraulic lifting 1400 mm, double hydropneumatic shock absorber

WORK U BOOM

Cataphoresis and powder painted boom

Independent opening and closing of the arms

Independent opening and closing of the tips

Self-leveling and hydraulic locking

Sliding protections

Trijet without nozzles

OILDRIVE 7 - 1 pair of quick couplings required on the tractor

ALA 500-600 BOOM

Cataphoresis and powder painted boom

Overlapping sequential opening and closing of the arms, right and left independent (ALA 500)

Sequential opening and closing of the side arms, right and left independent (ALA 600)

Self-leveling and hydraulic locking

Variable geometry

Sliding protections

Trijet without nozzles

OILDRIVE 7 - 1 pair of quick couplings required on the tractor

| Measure | Real tank capacity | Boom width | N. of sections | Circuit rinse tank capacity | Pump type | Control group | Drawbar | Towing eye | Wheels | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 22C | 2,400 lt | 15 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| 22C | 2,400 lt | 18 m | 7 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| 32C | 3,200 lt | 15 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| 32C | 3,200 lt | 18 m | 7 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| Measure | Real tank capacity | Boom width | N. of sections | Circuit rinse tank capacity | Pump type | Control group | Drawbar | Towing eye | Wheels | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 22C | 2,400 lt | 16 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| 22C | 2,400 lt | 18 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| 22C | 2,400 lt | 21 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| 32C | 3,200 lt | 16 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| 32C | 3,200 lt | 18 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| 32C | 3,200 lt | 21 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| Measure | Real tank capacity | Boom width | N. of sections | Circuit rinse tank capacity | Pump type | Control group | Drawbar | Towing eye | Wheels | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 22C | 2,400 lt | 18 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| 22C | 2,400 lt | 21 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| 32C | 3,200 lt | 18 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| 32C | 3,200 lt | 21 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

FRAME

Cataphoresis painted frame with stepladder and platform

Square axle 80 mm with adjustable wheelbase and track (min1650 - max2250)

Mechanical parking foot

TANK GROUP

Facilitated emptying polyethylene tank

Hinged lid with bayonet joint

Washing circuit system with independent tank

2 circuit rinse rotating jets

Handwashing tank

Empty level

FILLING AND FILTERING

M-PANEL: manual panel on the left side with centralized controls

3 way deviator for tank filling

2" camlock quick hitch for filling from external non-pressurized source

Inspectionable external suction filter

External selfcleaning delivery filter

GreenMix T30 premixer with parallelogram

Double hydraulic agitator through perforated tube and pressure agitators

DEVIOKIT: circuit rinse system even with full tank

Flowback: advanced anti-drip system

PUMP

Comet pump

Pump flow control kit for functional testing

PTO shaft (tractor side yoke 1" 3/8 Z6)

CONTROL GROUP

ISOBUS control unit compliant with ISO standard ISO 11783

Speed sensor on the wheel

Pressure sensor

Flowmeter

Differential pressure gauge

BAR SUSPENSION

Trolley lifting system

Self-leveling pendulum frame with jacks, shock absorbers and springs

Hydraulic lifting 1400 mm, double hydropneumatic shock absorber

WORK U BOOM

Cataphoresis and powder painted boom

Independent opening and closing of the arms

Independent opening and closing of the tips

Self-leveling and hydraulic locking

Sliding protections

Trijet without nozzles

OILDRIVE 7 - 1 pair of quick couplings required on the tractor

ALA 500-600 BOOM

Cataphoresis and powder painted boom

Overlapping sequential opening and closing of the arms, right and left independent (ALA 500)

Sequential opening and closing of the side arms, right and left independent (ALA 600)

Self-leveling and hydraulic locking

Variable geometry

Sliding protections

Trijet without nozzles

OILDRIVE 7 - 1 pair of quick couplings required on the tractor

| Measure | Real tank capacity | Boom width | N. of sections | Circuit rinse tank capacity | Pump type | Control group | Drawbar | Towing eye | Wheels | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| P22 | 2,400 lt | 16 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| P22 | 2,400 lt | 18 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| P22 | 2,400 lt | 21 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| P32 | 3,200 lt | 16 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| P32 | 3,200 lt | 18 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| P32 | 3,200 lt | 21 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| Measure | Real tank capacity | Boom width | N. of sections | Circuit rinse tank capacity | Pump type | Control group | Drawbar | Towing eye | Wheels | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| P22 | 2,400 lt | 18 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| P22 | 2,400 lt | 21 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| P22 | 2,400 lt | 24 m | 7 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| P32 | 3,200 lt | 18 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| P32 | 3,200 lt | 21 m | 5 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| P32 | 3,200 lt | 24 m | 7 | 300 lt | BPS 260 | BRAVO 180 | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

FRAME

Cataphoresis painted frame with stepladder and platform

Square axle 80 mm with adjustable wheelbase and track (min1650 - max2250)

Mechanical parking foot

Right side product holders

TANK GROUP

Facilitated emptying polyethylene tank

Hinged lid with bayonet joint

Washing circuit system with independent tank

2 circuit rinse rotating jets

Handwashing tank

Empty level

FILLING AND FILTERING

M-PANEL: manual panel on the left side with centralized controls

3 way deviator for tank filling

2" camlock quick hitch for filling from external non-pressurized source

Inspectionable external suction filter

External selfcleaning delivery filter

GreenMix T30 premixer with parallelogram

Double hydraulic agitator through perforated tube and pressure agitators

DEVIOKIT: circuit rinse system even with full tank

Flowback: advanced anti-drip system

PUMP

Comet pump

Pump flow control kit for functional testing

PTO shaft (tractor side yoke 1" 3/8 Z6)

CONTROL GROUP

Electronic DPAE adjustment

BRAVO 180 computer

Control panel for managing water and hydraulic functions

Speed sensor on the wheel

Flowmeter

Differential pressure gauge

BAR SUSPENSION

Parallelogram lifting system

Self-leveling pendulum frame with jacks, shock absorbers and springs

Hydraulic lifting 1500 mm, double hydropneumatic shock absorber

ALA 500-600 BOOM

Cataphoresis and powder painted boom

Overlapping sequential opening and closing of the arms, right and left independent (ALA 500)

Sequential opening and closing of the side arms, right and left independent (ALA 600)

Self-leveling and hydraulic locking

Variable geometry

Sliding protections

Trijet without nozzles

OILDRIVE 7 - 1 pair of quick couplings required on the tractor

In combination with the air sleeve, quick couplings to the tractor are not required (independent hydraulic pump).

| Measure | Real tank capacity | Boom width | N. of sections | Circuit rinse tank capacity | Pump type | Control group | Drawbar | Towing eye | Wheels | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| P22 | 2,400 lt | 16 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| P22 | 2,400 lt | 18 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| P22 | 2,400 lt | 21 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| P32 | 3,200 lt | 16 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| P32 | 3,200 lt | 18 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| P32 | 3,200 lt | 21 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| Measure | Real tank capacity | Boom width | N. of sections | Circuit rinse tank capacity | Pump type | Control group | Drawbar | Towing eye | Wheels | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| P22 | 2,400 lt | 18 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| P22 | 2,400 lt | 21 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| P22 | 2,400 lt | 24 m | 7 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| P32 | 3,200 lt | 18 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| P32 | 3,200 lt | 21 m | 5 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

| P32 | 3,200 lt | 24 m | 7 | 300 lt | BPS 260 | ISOBUS | Rigid | 40 mm | 270/95 R48 8 holes | 2,800 kg |

FRAME

Cataphoresis painted frame with stepladder and platform

Square axle 80 mm with adjustable wheelbase and track (min1650 - max2250)

Mechanical parking foot

Right side product holders

TANK GROUP

Facilitated emptying polyethylene tank

Hinged lid with bayonet joint

Washing circuit system with independent tank

2 circuit rinse rotating jets

Handwashing tank

Empty level

FILLING AND FILTERING

M-PANEL: manual panel on the left side with centralized controls

3 way deviator for tank filling

2" camlock quick hitch for filling from external non-pressurized source

Inspectionable external suction filter

External selfcleaning delivery filter

GreenMix T30 premixer with parallelogram

Double hydraulic agitator through perforated tube and pressure agitators

DEVIOKIT: circuit rinse system even with full tank

Flowback: advanced anti-drip system

PUMP

Comet pump

Pump flow control kit for functional testing

PTO shaft (tractor side yoke 1" 3/8 Z6)

CONTROL GROUP

ISOBUS control unit compliant with ISO standard ISO 11783

Speed sensor on the wheel

Pressure sensor

Flowmeter

Differential pressure gauge

BAR SUSPENSION

Parallelogram lifting system

Self-leveling pendulum frame with jacks, shock absorbers and springs (ALA 500-600)

Self-leveling double pendulum frame with jacks, shock absorbers and springs (ALA 400)

Anti-yaw system with ADIPOL springs (ALA 400)

Hydraulic lifting 1500 mm, double hydropneumatic shock absorber

ALA 500-600 BOOM

Cataphoresis and powder painted boom

Overlapping sequential opening and closing of the arms, right and left independent (ALA 500)

Sequential opening and closing of the side arms, right and left independent (ALA 600)

Self-leveling and hydraulic locking

Variable geometry

Sliding protections

Trijet without nozzles

OILDRIVE 7 - 1 pair of quick couplings required on the tractor

In combination with the air sleeve, quick couplings to the tractor are not required (independent hydraulic pump).