Variable chamber round baler with electronic variable geometry and 4 belts

EXTREME 2 is the new hybrid round baler with variable chamber and variable geometry that combines the winning characteristics of both fixed and variable chamber round balers. The machine has been designed to guarantee the greatest combination of shapes, pressures (up to 210 bar) and bale sizes up to 180 cm. EXTREME 2 offers a perfect balance between high performance and maximum ease of use, which makes it suitable for all types of farms.

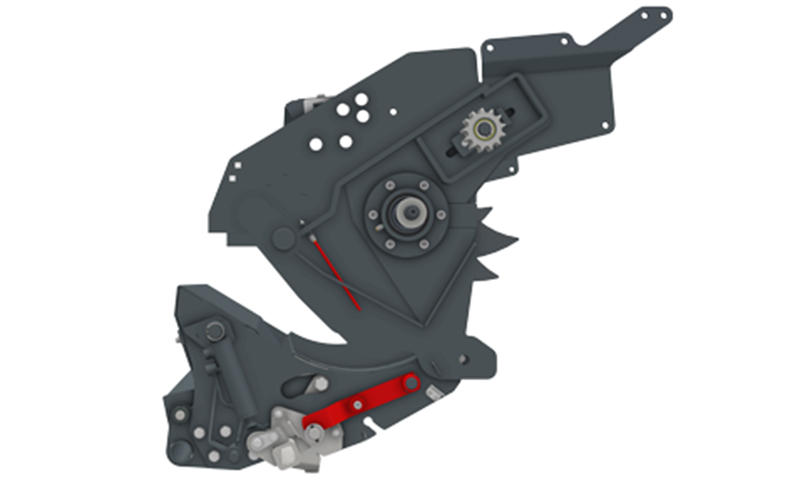

The geometry management within the variable chamber is made possible by a double rocker arm controlled by hydraulic cylinders. The first defines the pressure and the diameter of the bale with the possibility of creating a pre-chamber with zero pressure up to 1,1 m, while the second rocker automatically compensates the tension of the four clinched belts of width 277 mm during the formation of the bale. This allows to obtain enormous advantages for those who are attentive to the product quality.

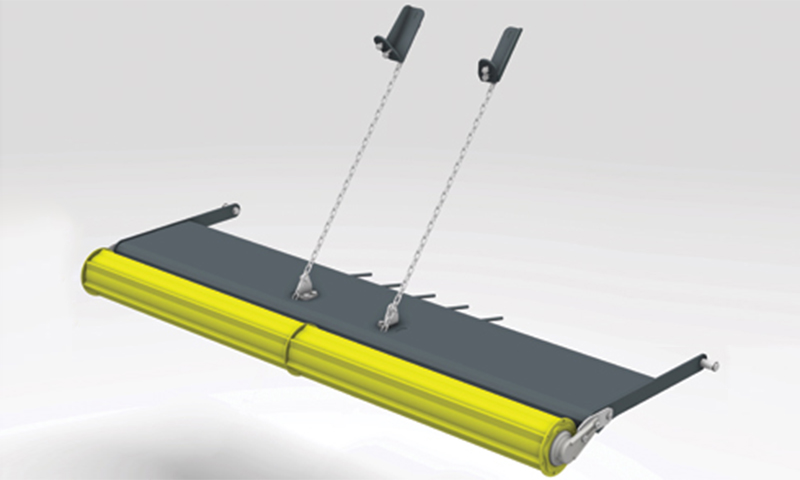

The large 2,2 m pick-up with pivoting wheels allows to operate even in the presence of not perfectly regular and abundant windrows. Harvest of the product is delicate with any type of forage, even in the case of leafy product. The machine can be equipped with a windrow press roller.

EXTREME series 2 series is polyvalent, in fact there are 4 feeding systems that can be requested: HTI with alternative feeder, HTR rotary feeder without cutting, HTC rotary feeder with 13 knives and HTU rotary feeder with 25 knives. The stars of all rotors are made of high strength steel to minimise wear during work.

EXTREME 2 ISOTRONIC is the latest generation version, updated with ISOBUS communication protocol. All the working parameters can be managed directly in a simple and intuitive way from the ISOBUS terminal in the tractor. A state-of-the-art equipment for both forage farms and the most demanding contractor

With EXTREME 2 it is possible to collect different types of product, both dry and wet, thanks to its versatility, with the variation of the chamber pressure (up to 210 bar) and the possibility of creating a zero pressure pre-chamber. All working parameters can be easily managed from the terminal in the cabin. A modular and versatile round baler thanks to the 4 different feeding types, ideal for all farms.

| Measure | Ø bale (min) | Ø bale (max) | Bale width | Pick-up width | Belts type | No. of belts | Tying | Wheels | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 266 HTI | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Clinched | 4 | Net | 400/60-15.5 | 48 kW | 3,000 kg |

| 266 HTI | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 48 kW | 3,000 kg |

| 286 HTI | 0.5 m | 1.8 m | 1.2 m | 2.2 m | Clinched | 4 | Net | 400/60-15.5 | 51 kW | 3,010 kg |

| 286 HTI | 0.5 m | 1.8 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 51 kW | 3,000 kg |

| Measure | Ø bale (min) | Ø bale (max) | Bale width | Pick-up width | Belts type | No. of belts | Tying | Wheels | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 266 HTR | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Clinched | 4 | Net | 400/60-15.5 | 48 kW | 3,300 kg |

| 266 HTR | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 48 kW | 3,300 kg |

| 286 HTR | 0.5 m | 1.8 m | 1.2 m | 2.2 m | Clinched | 4 | Net | 400/60-15.5 | 51 kW | 3,330 kg |

| 286 HTR | 0.5 m | 1.8 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 51 kW | 3,460 kg |

| Measure | Ø bale (min) | Ø bale (max) | Bale width | Pick-up width | Belts type | No. of belts | Tying | Wheels | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 266 HTC | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Clinched | 4 | Net | 400/60-15.5 | 48 kW | 3,520 kg |

| 266 HTC | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 48 kW | 3,440 kg |

| 286 HTC | 0.5 m | 1.8 m | 1.2 m | 2.2 m | Clinched | 4 | Net | 400/60-15.5 | 51 kW | 3,634 kg |

| 286 HTC | 0.5 m | 1.8 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 51 kW | 3,510 kg |

| Measure | Ø bale (min) | Ø bale (max) | Bale width | Pick-up width | Belts type | No. of belts | Tying | Wheels | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 266 HTU | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Clinched | 4 | Net | 400/60-15.5 | 48 kW | 3,540 kg |

| 266 HTU | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 48 kW | 3,550 kg |

| 286 HTU | 0.5 m | 1.8 m | 1.2 m | 2.2 m | Clinched | 4 | Net | 400/60-15.5 | 51 kW | 3,750 kg |

| 286 HTU | 0.5 m | 1.8 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 51 kW | 4,060 kg |

TRANSMISSION

Wide angle PTO shaft with slip clutch (HTI version)

Wide angle cam-shaft (HTR-HTC-HTU versions)

PTO 540 rpm

CONTROL GROUP

Multifunction electronic control unit ICON

FEEDING SYSTEM

Pick-up 220 cm with 4 tooth bars with pivoting wheels (HTI version)

Pick-up 220 cm with 4 tooth bars with pivoting wheels and crop roller (HTR-HTC-HTU versions)

Drop floor (HTR-HTC-HTU versions)

BALE COMPRESSION SYSTEM

Variable chamber with pre-starting chamber

Bale diameter electronic control

Electronic variable geometry

Hydraulic bale compression with electronic density adjustment

4 clinched belts, 277 mm width

4 closed loop belts, 277 mm width

Loading sensors

LUBRIFICATION

Automatic chain lubrication

Centralized manual greasing system

FRAME

Adjustable draw bar

Couple of shrinking cups

Ladder

LED road lights

Tires 400/60-15,5

Mother Regulation road homologation available without braking system

| Measure | Ø bale (min) | Ø bale (max) | Bale width | Pick-up width | Belts type | No. of belts | Tying | Wheels | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 266 HTI | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Clinched | 4 | Net | 400/60-15.5 | 48 kW | 2,940 kg |

| 266 HTI | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 48 kW | 2,950 kg |

| 286 HTI | 0.5 m | 1.8 m | 1.2 m | 2.2 m | Clinched | 4 | Net | 400/60-15.5 | 51 kW | 3,000 kg |

| 286 HTI | 0.5 m | 1.8 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 51 kW | 3,000 kg |

| Measure | Ø bale (min) | Ø bale (max) | Bale width | Pick-up width | Belts type | No. of belts | Tying | Wheels | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 266 HTR | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Clinched | 4 | Net | 400/60-15.5 | 48 kW | 3,320 kg |

| 266 HTR | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 48 kW | 3,300 kg |

| 286 HTR | 0.5 m | 1.8 m | 1.2 m | 2.2 m | Clinched | 4 | Net | 400/60-15.5 | 51 kW | 3,462 kg |

| 286 HTR | 0.5 m | 1.8 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 51 kW | 3,460 kg |

| Measure | Ø bale (min) | Ø bale (max) | Bale width | Pick-up width | Belts type | No. of belts | Tying | Wheels | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 266 HTC | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Clinched | 4 | Net | 400/60-15.5 | 48 kW | 3,410 kg |

| 266 HTC | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 48 kW | 3,410 kg |

| 286 HTC | 0.5 m | 1.8 m | 1.2 m | 2.2 m | Clinched | 4 | Net | 400/60-15.5 | 51 kW | 3,634 kg |

| 286 HTC | 0.5 m | 1.8 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 51 kW | 3,640 kg |

| Measure | Ø bale (min) | Ø bale (max) | Bale width | Pick-up width | Belts type | No. of belts | Tying | Wheels | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 266 HTU | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Clinched | 4 | Net | 400/60-15.5 | 51 kW | 3,550 kg |

| 266 HTU | 0.5 m | 1.65 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 51 kW | 3,550 kg |

| 286 HTU | 0.5 m | 1.8 m | 1.2 m | 2.2 m | Clinched | 4 | Net | 400/60-15.5 | 51 kW | 4,064 kg |

| 286 HTU | 0.5 m | 1.8 m | 1.2 m | 2.2 m | Endless | 4 | Net | 400/60-15.5 | 51 kW | 4,064 kg |

TRANSMISSION

Wide angle PTO shaft with slip clutch (HTI version)

Wide angle cam-shaft (HTR-HTC-HTU versions)

PTO 540 rpm

CONTROL GROUP

Complies with ISO 11783 standard

FEEDING SYSTEM

Pick-up 220 cm with 4 tooth bars with pivoting wheels (HTI version)

Pick-up 220 cm with 4 tooth bars with pivoting wheels and crop roller (HTR-HTC-HTU versions)

Drop floor (HTR-HTC-HTU versions)

BALE COMPRESSION SYSTEM

Variable chamber with pre-starting chamber

Bale diameter electronic control

Electronic variable geometry

Hydraulic bale compression with electronic density adjustment

4 clinched belts, 277 mm width

4 closed loop belts, 277 mm width

Loading sensors

LUBRIFICATION

Automatic chain lubrication

Centralized manual greasing system

FRAME

Adjustable draw bar

Couple of shrinking cups

Ladder

LED road lights

Tires 400/60-15,5

Mother Regulation road homologation available without braking system