Hydraulic folding pneumatic seed drill for cereals

PRIMAVERA is one of the largest pneumatic in-line seed drills for large cereals. The result of GASPARDO's century of experience in the sector, PRIMAVERA stands out for its reliability, robustness and precision. Based on a mounted or trailed frame (on request) with hydraulically closing side wings, it is available in 5 and 6 m versions, up to a maximum of 48 rows, ideal for sowing crops such as cereals and rape.

PRIMAVERA is highly versatile thanks to the sturdy structure of the seeding bar, with no less than 4 rows of coulter units widely spaced apart, which allow it to operate even on minimum tilled soils with the presence of crop residues. Thanks to the hydraulically folding side wings, the transport width of only 3 m allows easy road transport.

The renowned GASPARDO transmission system with oil-bath three-cam gearbox works in combination with pneumatic seed transport. This system benefits from the BY-PASS patent, which significantly increases forward speed, reducing seeding time and costs without compromising the uniformity of distribution across the entire working width, as well as operating in difficult conditions such as sowing on hillsides. To minimize seed waste, an electric seeding interruption system is available on request for the mechanical transmission version, ideal for headland turns.

High performance is ensured by the large hopper, which guarantees high autonomy, and by the oscillating seeding bar which, thanks to a floating system mounted on the frame, allows sowing even on uneven and hilly terrain. Furthermore, the possibility of choosing between two different types of coulter bodies, straight suffolk coulter or double disc, and between three different seed cover harrows, allows the farmer to always find the best solution for his needs.

For greater technological demands, PRIMAVERA ISOTRONIC is equipped with electric drive and ISOBUS communication system allowing digital control of the seed and all Precision Farming functions.

PRIMAVERA combines in a single machine high autonomy, good speed and working widths of up to 6 metres. The HEAVY DUTY frame and the 4-row arrangement of the units allow seeding even on minimum tilled soil, rich in stones and crop residues.

| Measure | Working width (min) | Transport width | N. of rows | Inter-row (min) | Seed hopper | Fertilizer hopper | Wheels | Weight |

|---|---|---|---|---|---|---|---|---|

| 500/40 | 5 m | 3 m | 40 | 12.5 cm | 1,500 lt | 0 lt | 13.0/55-16 | 1,920 kg |

| 600/40 | 6 m | 3 m | 40 | 15 cm | 1,500 lt | 0 lt | 13.0/55-16 | 1,960 kg |

| 600/48 | 6 m | 3 m | 48 | 12.5 cm | 1,500 lt | 0 lt | 13.0/55-16 | 2,020 kg |

| Measure | Working width (min) | Transport width | N. of rows | Inter-row (min) | Seed hopper | Fertilizer hopper | Wheels | Weight |

|---|---|---|---|---|---|---|---|---|

| 500/40 | 5 m | 3 m | 40 | 12.5 cm | 1,500 lt | 0 lt | 13.0/55-16 | 2,200 kg |

| 600/40 | 6 m | 3 m | 40 | 15 cm | 1,500 lt | 0 lt | 13.0/55-16 | 2,220 kg |

Tractor dipendent hydraulic fan drive

Gearbox oil cooler system with radiator

Sowing bar on 4 ranks

Single coulter pressure adjustment

External wings pressure regulation

The frame joints have a device which permits oscillating operations during work (with air chamber support wheels)

Floating frame nitrogen accumulator

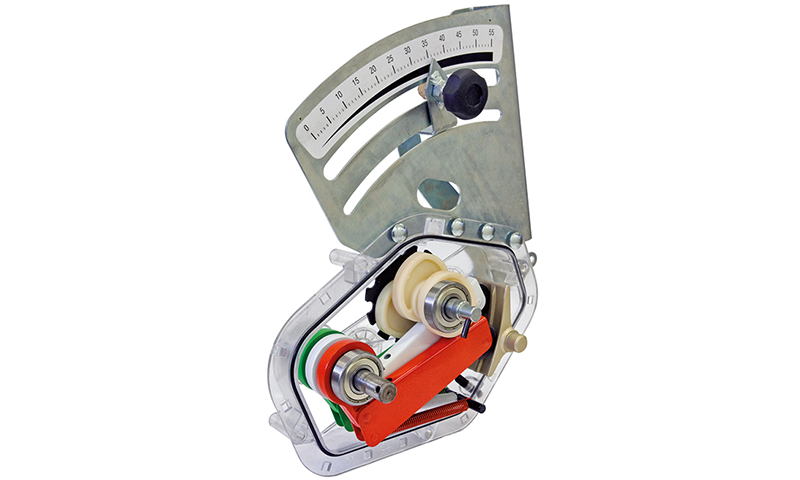

Calibration control

Calibration and emptying tray

Inspection footboard with ladder

Light kit (disassembled)

Warning boards (disassembled)

Row marker track in centre with Ø 450 mm disc and safety pin and inside overall work width

Row marker lock valves

Drive wheels 13.00/55 - 16 with double wheel track eradicators

Central dosing system with adjustment and dosing calibration “easy access” system

G1000 and F25-125 metering rollers for seed

Deviator seed flow lever for seed calibration

Slingshot for distributor exclusion

Electric seed level indicator

| Measure | Working width (min) | Transport width | N. of rows | Inter-row (min) | Seed hopper | Fertilizer hopper | Wheels | Weight |

|---|---|---|---|---|---|---|---|---|

| 500/40 | 5 m | 3 m | 40 | 12.5 cm | 1,500 lt | 0 lt | 13.0/55-16 | 1,920 kg |

| 600/40 | 6 m | 3 m | 40 | 15 cm | 1,500 lt | 0 lt | 13.0/55-16 | 2,070 kg |

| 600/48 | 6 m | 3 m | 48 | 12.5 cm | 1,500 lt | 0 lt | 13.0/55-16 | 2,150 kg |

| Measure | Working width (min) | Transport width | N. of rows | Inter-row (min) | Seed hopper | Fertilizer hopper | Wheels | Weight |

|---|---|---|---|---|---|---|---|---|

| 500/40 | 5 m | 3 m | 40 | 12.5 cm | 1,500 lt | 0 lt | 13.0/55-16 | 2,250 kg |

| 600/40 | 6 m | 3 m | 40 | 15 cm | 1,500 lt | 0 lt | 13.0/55-16 | 2,200 kg |

1 centralized volumetric doser for seed

Complies with ISO 11783 standard

ISOBUS GENIUS MASTER system

GPS speed sensor

Pneumatic seed distribution with tractor dependent fan drive

Tractor dipendent hydraulic fan drive

Gearbox oil cooler system with radiator

Sowing bar on 4 ranks

Single coulter pressure adjustment

External wings pressure regulation

The frame joints have a device which permits oscillating operations during work (with air chamber support wheels)

Floating frame nitrogen accumulator

Calibration control

Calibration and emptying tray

Inspection footboard with ladder

Light kit (disassembled)

Warning boards (disassembled)

Row marker track in centre with Ø 450 mm disc and safety pin and inside overall work width

Row marker lock valves

Drive wheels 13.00/55 - 16 with double wheel track eradicators

G1000 and F25-125 metering rollers for seed

Automatic deviator seed flow for seed calibration

Slingshot for distributor exclusion

Electric seed level indicator