Mounted sprayer

TEMPO is the professional sprayer designed to ensure work quality and high efficiency: its extensive standard equipment makes all the preliminary work and cleaning operations easy. Available with hydraulic booms and work widths up to 18 m, it can be enhanced with a variety of accessories, offering the customer the most suitable solution for their needs.

Solutions such as the water control panel that groups all functional valves for spreading, cleaning and loading increase the overall efficiency of the machine. Standard PREMIX makes it possible to work with great comfort and safety.

TEMPO is characterised by applications that make the most of all its potential. Compared to TEKO model from which it derives, the standard equipment is enhanced with additional systems such as FLOWBACK, which resets the pressure in the delivery pipes and the very useful manual water panel on the machine which contains all the main controls. This last application significantly facilitates and speeds up all loading and unloading operations. Thanks to OLIDRIVE, the main movements of the boom can be centrally controlled using a single pair of quick couplings of the tractor to supply oil to the hydraulic circuit of the machine.

In addition to the main tank with a capacity up to 1,200 L, TEMPO can be equipped with a 1,100 - 1,500 L accessory front tank. In addition to increasing the operating autonomy, meaning higher hourly production, this application ensures a greater balance between tractor and equipment, making it possible to use the system even in hilly conditions. The reduced total width and bevelled shape do not compromise the operator’s front view.

ISOTRONIC version, for the more demanding farmers and contractors, is also available with ISOBUS communication protocol for complete digital control of the equipment. Thanks to the different Universal Terminals available, all water, hydraulic and Precision Farming functions can be easily managed.

| Measure | Real tank capacity | Boom width | N. of sections | Circuit rinse tank capacity | Pump type | Control group | Hitch | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 800 | 860 lt | 12 m | 5 | 100 lt | BP 171 | BRAVO 180 | 3 point cat. II^N | 66 kW | 1,100 kg |

| 800 | 860 lt | 15 m | 5 | 100 lt | BP 171 | BRAVO 180 | 3 point cat. II^N | 66 kW | 1,100 kg |

| 1000 | 1,100 lt | 12 m | 5 | 100 lt | BP 171 | BRAVO 180 | 3 point cat. II^N | 66 kW | 1,125 kg |

| 1000 | 1,100 lt | 15 m | 5 | 100 lt | BP 171 | BRAVO 180 | 3 point cat. II^N | 66 kW | 1,125 kg |

| 1200 | 1,298 lt | 12 m | 5 | 127 lt | BP 171 | BRAVO 180 | 3 point cat. II^N | 66 kW | 1,180 kg |

| 1200 | 1,298 lt | 15 m | 5 | 127 lt | BP 171 | BRAVO 180 | 3 point cat. II^N | 66 kW | 1,180 kg |

| Measure | Real tank capacity | Boom width | N. of sections | Circuit rinse tank capacity | Pump type | Control group | Hitch | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 800 | 860 lt | 15 m | 5 | 100 lt | BP 171 | BRAVO 180 | 3 point cat. II^N | 66 kW | 1,090 kg |

| 800 | 860 lt | 18 m | 5 | 100 lt | BP 171 | BRAVO 180 | 3 point cat. II^N | 66 kW | 1,105 kg |

| 800 | 860 lt | 18 m | 7 | 100 lt | BP 171 | BRAVO 180 | 3 point cat. II^N | 66 kW | 1,105 kg |

| 1000 | 1,100 lt | 15 m | 5 | 100 lt | BP 171 | BRAVO 180 | 3 point cat. II^N | 66 kW | 1,110 kg |

| 1000 | 1,100 lt | 18 m | 5 | 100 lt | BP 171 | BRAVO 180 | 3 point cat. II^N | 66 kW | 1,125 kg |

| 1000 | 1,100 lt | 18 m | 7 | 100 lt | BP 171 | BRAVO 180 | 3 point cat. II^N | 66 kW | 910 kg |

| 1200 | 1,298 lt | 15 m | 5 | 127 lt | BP 171 | BRAVO 180 | 3 point cat. II^N | 66 kW | 1,160 kg |

| 1200 | 1,298 lt | 18 m | 5 | 127 lt | BP 171 | BRAVO 180 | 3 point cat. II^N | 66 kW | 1,180 kg |

| 1200 | 1,298 lt | 18 m | 7 | 127 lt | BP 171 | BRAVO 180 | 3 point cat. II^N | 66 kW | 1,160 kg |

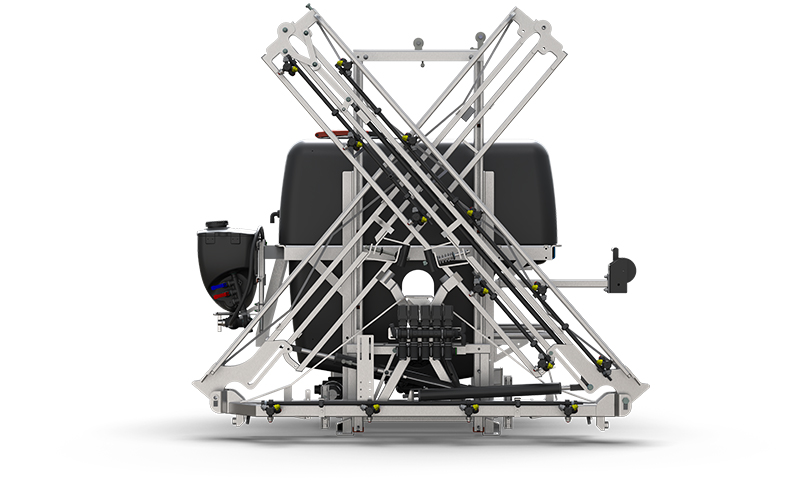

FRAME

Cataphoresis painted monobloc frame with stabilizing feet

Ladder with platform

Right side product holders

TANK GROUP

Total emptying polyethylene tank

Circuit rinse tank with connections and rinse tank rotating jet

Hinged lid with bayonet joint

Handwashing tank

FILLING AND FILTERING

M-PANEL: manual panel on the left side with centralized controls

3 way deviator for tank filling

Inspectionable external suction filter

External selfcleaning delivery filter

Double hydraulic agitator through perforated tube and pressure agitators

GreenMix T30 premixer

DEVIOKIT: circuit rinse system even with full tank

Flowback: advanced anti-drip system

PUMP

Comet pump

Pump flow control kit for functional testing

PTO shaft (tractor side yoke 1" 3/8 Z6)

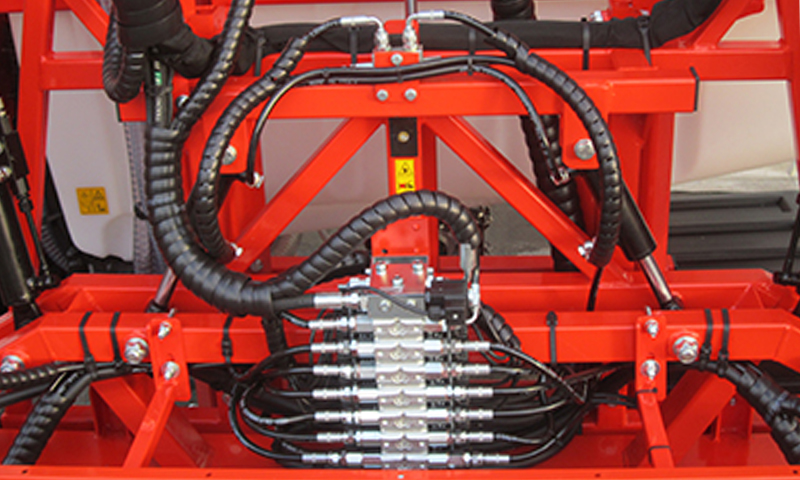

CONTROL GROUP

Electronic DPAE adjustment

BRAVO 180 computer

Control panel for managing water and hydraulic functions

Speed sensor on the wheel

Flowmeter

Differential pressure gauge

START BOOM

Cataphoresis and powder painted boom

Hydraulic lifting 1000 mm, double hydropneumatic shock absorber

Open/close arms in sequence, right/left independent

Hydraulic self-leveling with automatic locking system

Trijet without nozzles

OILDRIVE 4 - 1 pair of quick couplings required on the tractor

WORK U BOOM

Cataphoresis and powder painted boom

Hydraulic lifting 1000 mm, double hydropneumatic shock absorber

Independent opening and closing of the arms

Independent opening and closing of the tips

Self-leveling and hydraulic locking

Sliding protections

Trijet without nozzles

OILDRIVE 7 - 1 pair of quick couplings required on the tractor

| Measure | Real tank capacity | Boom width | N. of sections | Circuit rinse tank capacity | Pump type | Control group | Hitch | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 800 | 860 lt | 15 m | 5 | 100 lt | BP 171 | ISOBUS | 3 point cat. II^N | 66 kW | 1,120 kg |

| 800 | 860 lt | 18 m | 5 | 100 lt | BP 171 | ISOBUS | 3 point cat. II^N | 66 kW | 1,100 kg |

| 800 | 860 lt | 18 m | 7 | 100 lt | BP 171 | ISOBUS | 3 point cat. II^N | 66 kW | 1,100 kg |

| 1000 | 1,100 lt | 15 m | 5 | 100 lt | BP 171 | ISOBUS | 3 point cat. II^N | 66 kW | 1,220 kg |

| 1000 | 1,100 lt | 18 m | 5 | 100 lt | BP 171 | ISOBUS | 3 point cat. II^N | 66 kW | 1,125 kg |

| 1000 | 1,100 lt | 18 m | 7 | 100 lt | BP 171 | ISOBUS | 3 point cat. II^N | 66 kW | 1,125 kg |

| 1200 | 1,298 lt | 15 m | 5 | 127 lt | BP 171 | ISOBUS | 3 point cat. II^N | 66 kW | 1,180 kg |

| 1200 | 1,298 lt | 18 m | 5 | 127 lt | BP 171 | ISOBUS | 3 point cat. II^N | 66 kW | 1,190 kg |

| 1200 | 1,298 lt | 18 m | 7 | 127 lt | BP 171 | ISOBUS | 3 point cat. II^N | 66 kW | 1,180 kg |

FRAME

Cataphoresis painted monobloc frame with stabilizing feet

Ladder with platform

Right side product holders

TANK GROUP

Total emptying polyethylene tank

Circuit rinse tank with connections and rinse tank rotating jet

Hinged lid with bayonet joint

Handwashing tank

FILLING AND FILTERING

M-PANEL: manual panel on the left side with centralized controls

3 way deviator for tank filling

Inspectionable external suction filter

External selfcleaning delivery filter

Double hydraulic agitator through perforated tube and pressure agitators

GreenMix T30 premixer

DEVIOKIT: circuit rinse system even with full tank

Flowback: advanced anti-drip system

PUMP

Comet pump

Pump flow control kit for functional testing

PTO shaft (tractor side yoke 1" 3/8 Z6)

CONTROL GROUP

ISOBUS control unit compliant with ISO standard ISO 11783

Speed sensor on the tractor wheel

Pressure sensor

Flowmeter

Differential pressure gauge

WORK U BOOM

Cataphoresis and powder painted boom

Hydraulic lifting 1000 mm, double hydropneumatic shock absorber

Independent opening and closing of the arms

Independent opening and closing of the tips

Self-leveling and hydraulic locking

Sliding protections

Trijet without nozzles

OILDRIVE 7 - 1 pair of quick couplings required on the tractor