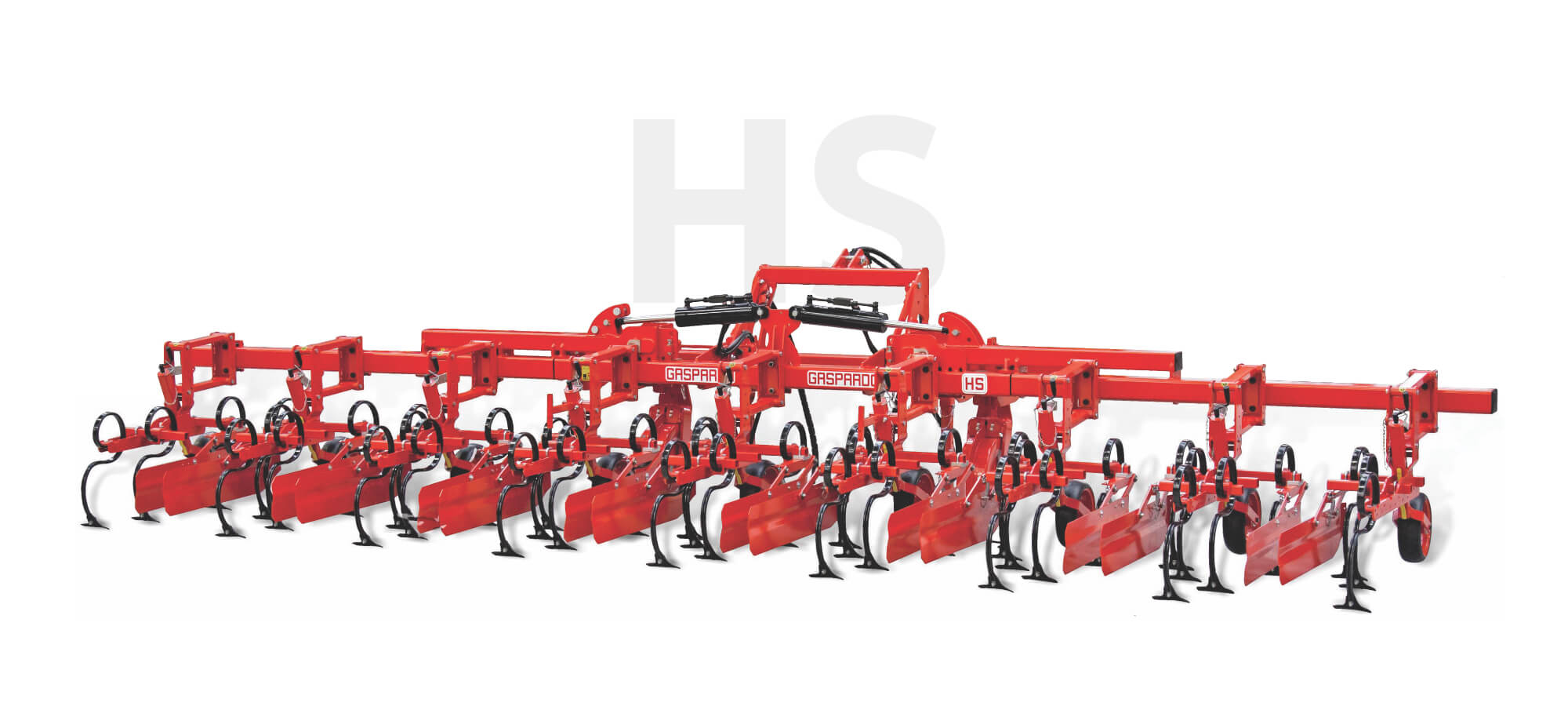

Hydraulic folding frame row-crop cultivator compact frame transport width 2,5 m

Traditionally specialists in precision planting, GASPARDO is also recognized for the reliability and operational capacity of its row crop cultivators, carefully designed for inter-row tilling of the main extensive, cereal and horticultural crops. The HS model is characterised by the frame with hydraulically folding side wings of the mounted type and is available in the “Beet” and “Corn” versions up to a maximum of 18 rows.

GASPARDO row crop cultivator element is characterised by high-level structural solutions such as the robust double parallelogram connection system with high ground clearance with preload spring, quick release and solidly fixed elements. These have a staggered arrangement of the “Superflow” springs which allows both an easy flow of soil without any risk of clogging and mounting different types of working parts and side protections according to the different operating requirements.

GASPARDO row crop cultivator element is coupled to the sturdy frame, characterised by a single beam structure with hydraulically folding side wings that allows a transport footprint of only 2.5 m for versions up to 12 rows. Thanks to the automatic locking device of the side wings, transport is safe and stable. In the versions equipped with fertilizer spreader, the structure is of the double frame type, to offer maximum strength; 400 mm load-bearing wheels are fitted as standard, an optimal solution especially for large working widths. For the compact basic versions, not equipped with fertilizer spreader, front coupling to the tractor is available on request.

Operational efficiency in the field can be improved thanks to the fertilizer spreader, allowing the elimination of weeds, distribution and burying of the fertilizer to be concentrated in a single pass. For the versions from 12 to 18 rows, the fertilizer spreader is of the PA1 mounted front hopper type, while for the versions up to 8 rows, the classic hopper mounted on the frame is available with a capacity of 950 l both in painted sheet metal and in stainless steel.

To increase the working precision in the field, the HS model can be combined with the SMART DRIVING system (on versions up to 12 rows with 45-50 inter-spacing without fertilizer spreader), an independent group applied between the tractor and the row crop cultivator that allows to drive automatically through the rows allowing to bring the blades closer to the plant up to 3 cm even at high forward speeds. To ensure effective motion transmission, the double drive wheel is equipped with teeth to increase traction on the ground.

HS is the ideal model for medium to large farms and contractors who require high-performance and high-precision row crop cultivators.

| N. of rows | Inter-row (min) | Fertilizer | Fertilizer hopper | N. of tillage units | Tillage unit | Hitch | Transport width | Weight |

|---|---|---|---|---|---|---|---|---|

| 6 | 45 cm | - | - | 7 | 3MP | 3 point cat. II^ | 2.5 m | 810 kg |

| 6 | 45 cm | - | - | 7 | 3MDD | 3 point cat. II^ | 2.5 m | 810 kg |

| 6 | 45 cm | - | - | 7 | 3ZD | 3 point cat. II^ | 2.5 m | 850 kg |

| 12 | 45 cm | - | - | 13 | 3MP | 3 point cat. II^ | 2.5 m | 1,290 kg |

| 12 | 45 cm | - | - | 13 | 3MDD | 3 point cat. II^ | 2.5 m | 1,290 kg |

| 12 | 45 cm | - | - | 13 | 3ZD | 3 point cat. II^ | 2.5 m | 1,320 kg |

| N. of rows | Inter-row (min) | Fertilizer | Fertilizer hopper | N. of tillage units | Tillage unit | Hitch | Transport width | Weight |

|---|---|---|---|---|---|---|---|---|

| 4 | 75 cm | - | - | 5 | 3MD | 3 point cat. II^ | 2.5 m | 670 kg |

| 4 | 75 cm | - | - | 5 | 3ZD | 3 point cat. II^ | 2.5 m | 700 kg |

| 4 | 75 cm | - | - | 5 | 5MP | 3 point cat. II^ | 2.5 m | 720 kg |

| 4 | 75 cm | - | - | 5 | 5MDD | 3 point cat. II^ | 2.5 m | 720 kg |

| 6 | 75 cm | - | - | 7 | 3MD | 3 point cat. II^ | 2.5 m | 830 kg |

| 6 | 75 cm | - | - | 7 | 3ZD | 3 point cat. II^ | 2.5 m | 870 kg |

| 6 | 75 cm | - | - | 7 | 5MP | 3 point cat. II^ | 2.5 m | 900 kg |

| 6 | 75 cm | - | - | 7 | 5MDD | 3 point cat. II^ | 2.5 m | 900 kg |

| 7 | 60 cm | - | - | 8 | 3MP | 3 point cat. II^ | 2.5 m | 900 kg |

| 7 | 60 cm | - | - | 8 | 3MDD | 3 point cat. II^ | 2.5 m | 910 kg |

| 8 | 75 cm | - | - | 9 | 3MD | 3 point cat. II^ | 2.5 m | 990 kg |

| 8 | 75 cm | - | - | 9 | 3ZD | 3 point cat. II^ | 2.5 m | 1,050 kg |

| 8 | 75 cm | - | - | 9 | 5MP | 3 point cat. II^ | 2.5 m | 1,090 kg |

| 8 | 75 cm | - | - | 9 | 5MDD | 3 point cat. II^ | 2.5 m | 1,090 kg |

| 12 | 75 cm | - | - | 13 | 3MD | 3 point cat. II^ | 3.83 m | 1,880 kg |

| 12 | 75 cm | - | - | 13 | 3ZD | 3 point cat. II^ | 3.83 m | 1,960 kg |

| 12 | 75 cm | - | - | 13 | 5MP | 3 point cat. II^ | 3.83 m | 2,030 kg |

| 12 | 75 cm | - | - | 13 | 5MDD | 3 point cat. II^ | 3.83 m | 2,040 kg |

TRACTOR CONNECTION

3 point hitch cat. II^

FRAME

Iron wheels for working depth adjustment

Compact frame compatible only with front fertilizer spreader PA

Road transport protections

Warning boards and road lights (disassembled)

Hydraulic distributors required: 2

TILLAGE UNIT

5MP = 5 tines and 2 protection plates

5MDD = 5 tines and 2 toothed disc protections

3ZD corn = 3 hoes and 2 discs

3MD = 3 tines and 2 discs

3MP = 3 tines and 2 protection plates

3MDD = 3 tines and 2 toothed discs protections

3ZD sugar beet = 3 hoes and 2 discs

Wheels supplied = number of rows +1

| N. of rows | Inter-row (min) | Fertilizer | Fertilizer hopper | N. of tillage units | Tillage unit | Hitch | Transport width | Weight |

|---|---|---|---|---|---|---|---|---|

| 8 | 45 cm | Painted sheet metal | 1x950 l | 9 | 3MP | 3 point cat. II^ | 2.5 m | 1,370 kg |

| 8 | 45 cm | Painted sheet metal | 1x950 l | 9 | 3MDD | 3 point cat. II^ | 2.5 m | 1,370 kg |

| N. of rows | Inter-row (min) | Fertilizer | Fertilizer hopper | N. of tillage units | Tillage unit | Hitch | Transport width | Weight |

|---|---|---|---|---|---|---|---|---|

| 4 | 75 cm | Painted sheet metal | 1x950 l | 5 | 5MP | 3 point cat. II^ | 2.5 m | 1,060 kg |

| 4 | 75 cm | Painted sheet metal | 1x950 l | 5 | 5MDD | 3 point cat. II^ | 2.5 m | 1,060 kg |

| 4 | 75 cm | Stainless steel | 1x950 l | 5 | 3ZD | 3 point cat. II^ | 2.5 m | 1,020 kg |

| 4 | 75 cm | Stainless steel | 1x950 l | 5 | 5MP | 3 point cat. II^ | 2.5 m | 1,040 kg |

| 4 | 75 cm | Stainless steel | 1x950 l | 5 | 5MDD | 3 point cat. II^ | 2.5 m | 1,040 kg |

| 6 | 75 cm | Painted sheet metal | 1x950 l | 7 | 3MD | 3 point cat. II^ | 2.5 m | 1,230 kg |

| 6 | 75 cm | Painted sheet metal | 1x950 l | 7 | 5MP | 3 point cat. II^ | 2.5 m | 1,310 kg |

| 6 | 75 cm | Painted sheet metal | 1x950 l | 7 | 5MDD | 3 point cat. II^ | 2.5 m | 1,310 kg |

| 6 | 75 cm | Stainless steel | 1x950 l | 7 | 3MD | 3 point cat. II^ | 2.5 m | 1,210 kg |

| 6 | 75 cm | Stainless steel | 1x950 l | 7 | 3ZD | 3 point cat. II^ | 2.5 m | 1,250 kg |

| 6 | 75 cm | Stainless steel | 1x950 l | 7 | 5MP | 3 point cat. II^ | 2.5 m | 1,290 kg |

| 6 | 75 cm | Stainless steel | 1x950 l | 7 | 5MDD | 3 point cat. II^ | 2.5 m | 1,290 kg |

| 7 | 60 cm | Painted sheet metal | 1x950 l | 8 | 3MP | 3 point cat. II^ | 2.5 m | 1,310 kg |

| 7 | 60 cm | Painted sheet metal | 1x950 l | 8 | 3MDD | 3 point cat. II^ | 2.5 m | 1,320 kg |

| 7 | 60 cm | Stainless steel | 1x950 l | 8 | 3MP | 3 point cat. II^ | 2.5 m | 1,290 kg |

| 7 | 60 cm | Stainless steel | 1x950 l | 8 | 3MDD | 3 point cat. II^ | 2.5 m | 1,300 kg |

| 8 | 75 cm | Painted sheet metal | 1x950 l | 9 | 3MD | 3 point cat. II^ | 2.5 m | 1,410 kg |

| 8 | 75 cm | Painted sheet metal | 1x950 l | 9 | 5MP | 3 point cat. II^ | 2.5 m | 1,500 kg |

| 8 | 75 cm | Painted sheet metal | 1x950 l | 9 | 5MDD | 3 point cat. II^ | 2.5 m | 1,500 kg |

| 8 | 75 cm | Stainless steel | 1x950 l | 9 | 3ZD | 3 point cat. II^ | 2.5 m | 1,440 kg |

| 8 | 75 cm | Stainless steel | 1x950 l | 9 | 5MP | 3 point cat. II^ | 2.5 m | 1,480 kg |

| 8 | 75 cm | Stainless steel | 1x950 l | 9 | 5MDD | 3 point cat. II^ | 2.5 m | 1,480 kg |

TRACTOR CONNECTION

3 point hitch cat. II^

TRANSMISSION

B2 Z6-Z6 PTO shaft (not present on 4-row machine)

FRAME

Iron wheels for working depth adjustment

2 machine support wheels

Road transport protections

Warning boards and road lights (disassembled)

Hydraulic distributors required: 2

FERTILIZER

Centralized SPEEDY SET adjustment for MINIMAX fertilizer meters

Pneumatic fertilizer transport for outer rows (not present on 4-row maize machine)

Double drive transmission wheel with loading spring mounted on ball bearings

Standard outer tine releases for HS 6 rows and 8 rows

Hopper windows for fertilizer level control

TILLAGE UNIT

5MP = 5 tines and 2 protection plates

5MDD = 5 tines and 2 toothed disc protections

3ZD corn = 3 hoes and 2 discs

3MD = 3 tines and 2 discs

3MP = 3 tines and 2 protection plates

3MDD = 3 tines and 2 toothed discs protections

3ZD sugar beet = 3 hoes and 2 discs

Wheels supplied = number of rows +1