Mounted pneumatic precision planter with hydraulic vertically-folding frame and floating wings

CHRONO 500 is the latest model in the range with which MASCHIO GASPARDO intends to share the experience gained so far in the precision farming sector. The high speed planting (up to 15 km/h), together with the high versatility of the CHRONO element, allows to excel in every situation. From conventional to minimum tillage to direct seeding, CHRONO 500 ensures seed deposition in the best conditions contributing to uniform germination. CHRONO 500 is available in fixed or transformable version by varying the distance between the planting units. Equipped with a mounted frame with folding and floating wings, CHRONO 500 is available in 8 row version with 70 cm or 75 cm spacing, 12 row version with 45 cm or 50 cm spacing.

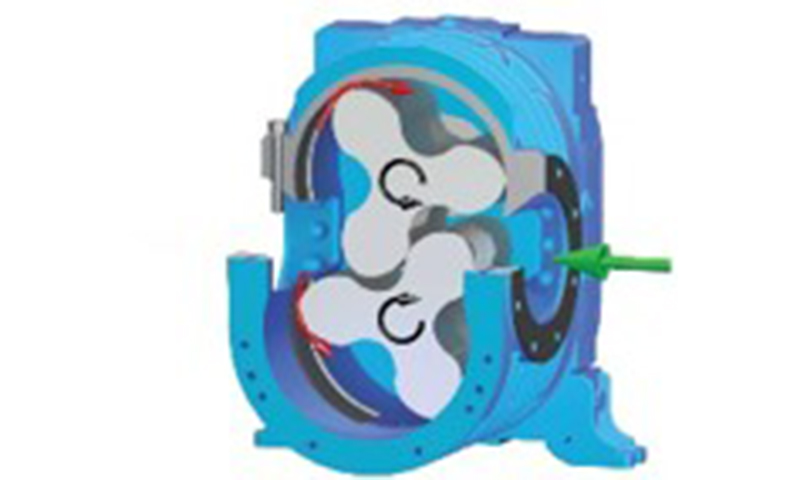

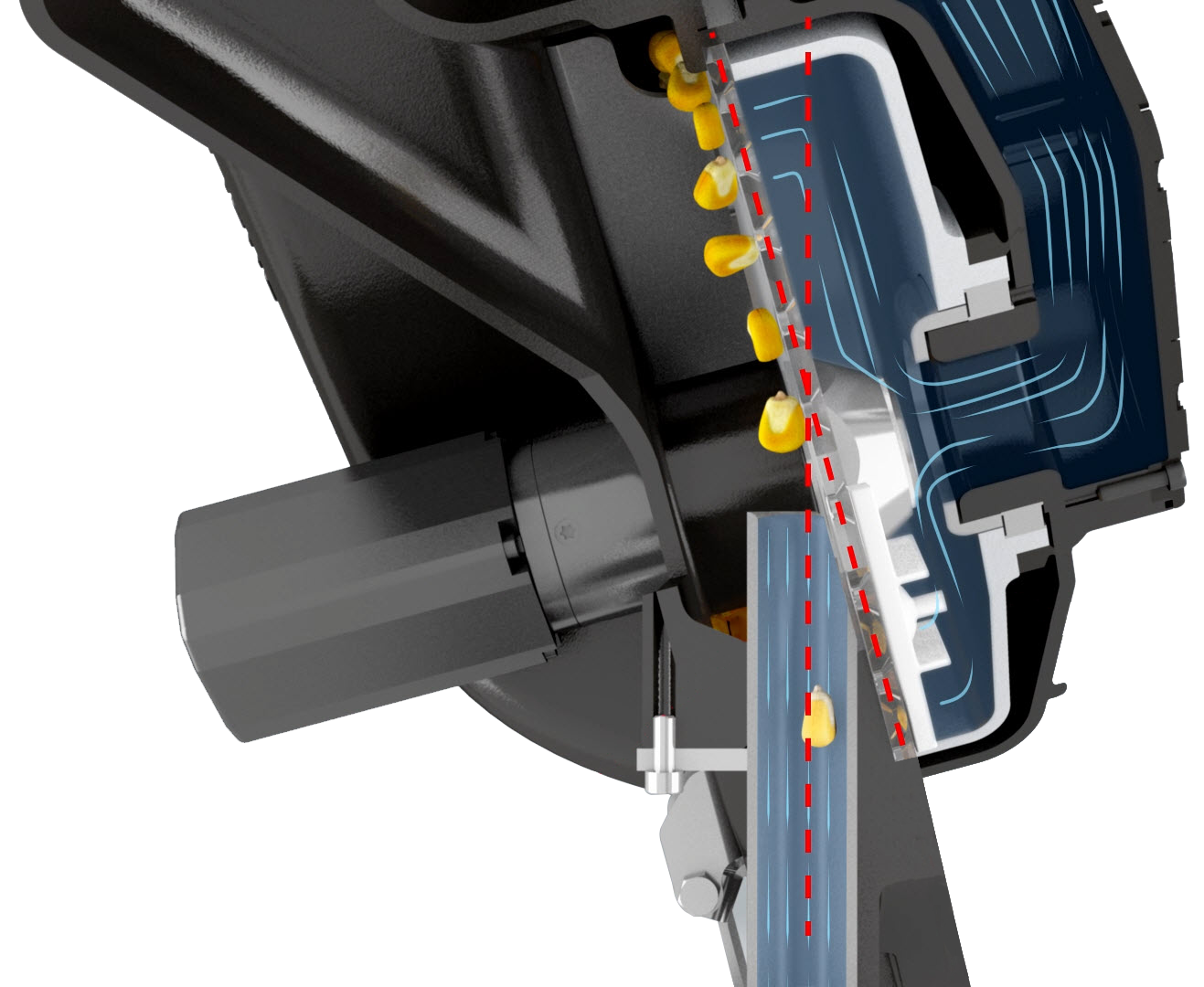

CHRONO planting unit features the most advanced solutions available on new-generation precision planters. The innovative independent pneumatic system uses a lobe compressor and varies the air flow according to the characteristics of the seed. Whether small seeds (rape) or larger seeds (maize, hemispherical seeds such as soya beans or seeds with a more irregular shape such as sunflowers), pneumatic transport minimises seed bounce inside the seed tube by maximising the regularity with which it is positioned in the seeding furrow, even at high speeds.

The CHRONO planting unit uses a robust double parallelogram connection system with AIR SPRING which allows the unit's ground pressure to be adjusted directly from the tractor cab up to a maximum of 300 kg. The ISOTRONIC transmission, standard on all CHRONO planting units, uses the ISOBUS communication protocol and the GENIUS MASTER interface; it is possible to take advantage of all Precision Farming features for planting, fertilising and distribution of microgranular products.

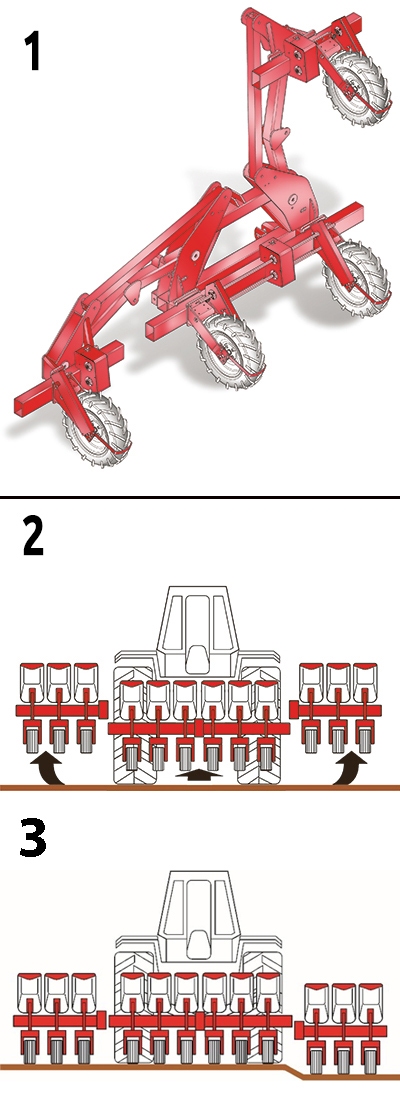

The mounted frame with folding and floating wings allows the 6 m working width to be quickly changed to only 3 m for transport, making it very easy to move around even on the road. During planting, the floating frame allows the soil profile to be followed as closely as possible. The WINGS UP system is activated automatically when the planter is lifted by selectively acting on the side sections of the frame; by raising them to a higher level than the rest of the machine, agility increases when manoeuvring at the headlands, on slopes or when working on fields with raised edges.

The CHRONO 500 frame is available in two configurations: fixed or transformable. It is possible to change from 8 to 12 rows and vice versa. In fixed configuration, the planter is available in four versions:

- 8 rows with 70 cm row spacing;

- 8 rows with 75 cm row spacing;

- 12 rows with 45 cm row spacing;

- 12 rows with 50 cm row spacing.

The 8 row version (70 or 75 cm row spacing) can be converted into a 12 row planter with a spacing between planting units of 45 cm or 50 cm depending on the chosen version. The conversion involves 4 planting units that are added to or removed from the planter and repositioned using the transport and storage trolley. The highly ergonomic process allows two operators to complete the conversion in less than 2 hours.

CHRONO 500 is a high-speed precision planter that maximises yield during field operations. Versatile and reliable, it adapts to the agronomic needs of different crops.

| N. of rows | Inter-row | Fertilizer | Fertilizer hopper | Total width | Frame length | Frame section | N. of wheels | Wheel position | Wheels | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 75 cm | - | - | 3 m | 5.8 m | 150x100 mm | 4 | Rear | 7.50-15 | 2,820 kg |

| 12 | 45-75 cm | - | - | 3 m | 5.8 m | 150x100 mm | 4 | Front | 22X11.00-10 | 3,840 kg |

| 12 | 50 cm | - | - | 3 m | 5.8 m | 150x100 mm | 4 | Front | 22X11.00-10 | 3,240 kg |

| N. of rows | Inter-row | Fertilizer | Fertilizer hopper | Total width | Frame length | Frame section | N. of wheels | Wheel position | Wheels | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 75 cm | - | - | 3 m | 5.8 m | 150x100 mm | 4 | Rear | 7.50-15 | 2,870 kg |

| 12 | 45-70 cm | - | - | 3 m | 5.8 m | 150x100 mm | 4 | Front | 22X11.00-10 | 3,980 kg |

| 12 | 45-75 cm | - | - | 3 m | 5.8 m | 150x100 mm | 4 | Front | 22X11.00-10 | 3,980 kg |

| 12 | 50 cm | - | - | 3 m | 5.8 m | 150x100 mm | 4 | Front | 22X11.00-10 | 3,370 kg |

| 12 | 50-75 cm | - | - | 3 m | 5.8 m | 150x100 mm | 4 | Front | 22X11.00-10 | 3,980 kg |

| N. of rows | Inter-row | Fertilizer | Fertilizer hopper | Total width | Frame length | Frame section | N. of wheels | Wheel position | Wheels | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 75 cm | - | - | 3 m | 5.8 m | 150x100 mm | 4 | Rear | 7.50-15 | 3,410 kg |

| N. of rows | Inter-row | Fertilizer | Fertilizer hopper | Total width | Frame length | Frame section | N. of wheels | Wheel position | Wheels | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 12 | 45-75 cm | - | - | 3 m | 5.8 m | 150x100 mm | 4 | Front | 22X11.00-10 | 4,550 kg |

| 12 | 50 cm | - | - | 3 m | 5.8 m | 150x100 mm | 4 | Front | 22X11.00-10 | 4,220 kg |

| N. of rows | Inter-row | Fertilizer | Fertilizer hopper | Total width | Frame length | Frame section | N. of wheels | Wheel position | Wheels | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 75 cm | - | - | 3 m | 5.8 m | 150x100 mm | 4 | Rear | 7.50-15 | 3,460 kg |

| 12 | 45-70 cm | - | - | 3 m | 5.8 m | 150x100 mm | 4 | Front | 22X11.00-10 | 4,440 kg |

| 12 | 45-75 cm | - | - | 3 m | 5.8 m | 150x100 mm | 4 | Front | 22X11.00-10 | 4,440 kg |

| 12 | 50-75 cm | - | - | 3 m | 5.8 m | 180x180 mm | 4 | Front | 22X11.00-10 | 4,440 kg |

| N. of rows | Inter-row | Fertilizer | Fertilizer hopper | Total width | Frame length | Frame section | N. of wheels | Wheel position | Wheels | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 12 | 45-75 cm | - | - | 3 m | 5.8 m | 150x100 mm | 4 | Front | 22X11.00-10 | 4,630 kg |

| 12 | 50 cm | - | - | 3 m | 5.8 m | 150x100 mm | 4 | Front | 22X11.00-10 | 4,300 kg |

| 12 | 50-75 cm | - | - | 3 m | 5.8 m | 150x100 mm | 4 | Front | 22X11.00-10 | 4,630 kg |

TRACTOR CONNECTION

3 point hitch cat. III^

TRANSMISSION

PTO 1000 rpm

R2 Z6-Z6 PTO shaft with freewheel

FRAME

Centralized AIR SPRING pressure adjustment via ISOBUS terminal, 1 setting

AIR SPRING pneumatic system tractor-dependent

Frame opening/closing safety, hydraulic control from the cabin (also operable from ISOBUS terminal)

Hydraulic row marker, trace central tractor and wheel (with Ø320 mm disc)

Bee safeguarding deflector hoses

Warning boards and road lights (disassembled)

CHRONO SEEDING UNIT

Capacity 60 l

ISOTRONIC transmission

AIR SPRING spring for ground pressure adjustment

Hydraulic lobe volumetric compressor

1 seed disc kit with cleaner per element (specify seed) for fixed machine

2 seed disc kits with cleaner per element (specify seed) for convertible machine (from 12 to 8 rows)

Rubber seed press wheel

1"X14" "V" rubber press wheels

Aluminum distributor lid

VORTEX pre-filter

MICROGRANULATOR (where present)

Capacity 16 l

ISOTRONIC transmission

FERTILIZER (predisposition for PA1) (where present)

Conveyor 8/12 outlets prepared for PA1

Coulter single disc fertilizer with AIR SPRING

ELECTRONIC

ISOBUS control unit compliant with ISO standard ISO 11783

ISOBUS GENIUS SMART system

- E.jpg)