Semi-mounted plough with shear bolt safety system

UNICO MAX, a semi-mounted reversible plough for in furrow and/or on land ploughing with a number of bodies ranging from 6 to 9, is packed full of quality and technology, delivering extremely high performance, including multiple working position correction and safety systems to handle the combined tasks of soil aeration, crop residue burial and incorporation. Available in an up to 9-bodies configuration, it is suitable for tractors with horsepower up to 500 HP.

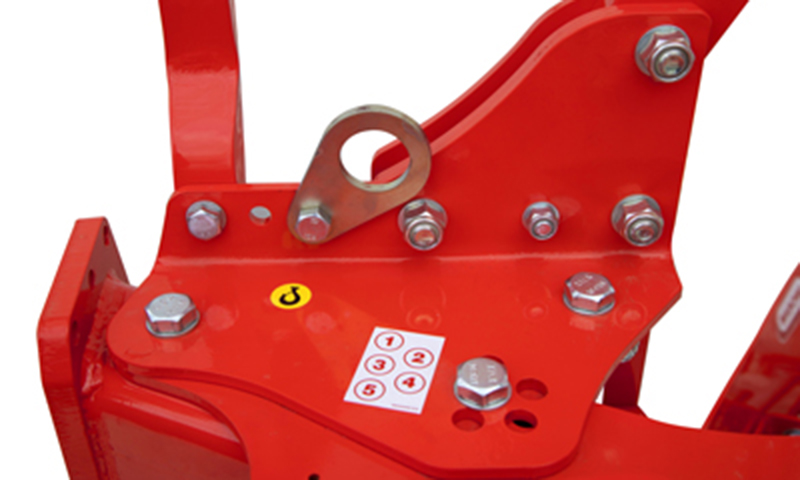

The modular design means a standard frame built to accommodate six, seven or eight plough bodies, with the option of attaching an additional body using a bolted-on connection plate, meaning coupling can be done in a matter of seconds. Working width can be adjusted by means of the “PASSO” system with "STEP-BY-STEP" type setting, which has 5 bolt adjustment options, or the "VARIO" solution featuring a non-stop hydraulic adjustment system with automatic memory: in the latter case, settings are made by suitably adjusting hydraulic power unit's relevant controls.

The central adjustment rod – which can be mechanical or hydraulic – creates a triangular structure that allows the forces to be transferred straight to the rear wheel. This results in a stiffer frame structure, stopping it from bending and thus improving the strength of the whole structure during ploughing.

In furrow/on land version available on request. With a 300mm-wide front wheel, the implement delivers consistent working depth as well as the assurance that it will follow the contours of the ground more accurately. This feature comes with considerable advantages, such as elimination of the plough sole resulting from wheelslip in the seed furrow, reduced wear on the inside of tyres, and less vibrations.

For tougher jobs, there is the choice of two setups. The HD version - which still has the same 160x160 cross-section frame with 10mm diameter and shear bolt safety system - takes the sturdy structure to the next level with reinforced plates for attaching the plough beams, 15mm-thick plough beam mounting plates, plough beams made with larger cross-sections 90x40 mm with a maximum clearance of 90 cm, and knife coulter on all plough bodies. Alternatively, the NSH Non-Stop Hydraulic system has hydraulic cylinders for each plough body - with a pre-charge that can be hydraulically adjusted from the cab - enabling the plough bodies to be lifted in the event of impact, returning them to the right position as soon as they have cleared the obstacle.

| Measure | No. of bodies | Bodies working width | Inter-body clearance | Under beam clearance STD | Power required HP | Power required KW | Weight |

|---|---|---|---|---|---|---|---|

| 6+0 | 6 | 13.8-15.7-17.7-19.7-21.7 in | 41.34 in | 31.5 in | 220-260 hp | 164-194 kW | 8,179.07 lb |

| 7+0 | 7 | 13.8-15.7-17.7-19.7-21.7 in | 41.34 in | 31.5 in | 260-300 hp | 194-224 kW | 8,939.65 lb |

| 8+0 | 8 | 13.8-15.7-17.7-19.7-21.7 in | 41.34 in | 31.5 in | 300-339 hp | 224-253 kW | 9,722.29 lb |

| Measure | No. of bodies | Bodies working width | Inter-body clearance | Under beam clearance STD | Power required HP | Power required KW | Weight |

|---|---|---|---|---|---|---|---|

| 6+0 | 6 | 11.8-21.7 in | 41.34 in | 31.5 in | 220-260 hp | 164-194 kW | 8,520.78 lb |

| 7+0 | 7 | 11.8-21.7 in | 41.34 in | 31.5 in | 260-300 hp | 194-224 kW | 9,369.55 lb |

| 8+0 | 8 | 11.8-21.7 in | 41.34 in | 31.5 in | 300-339 hp | 224-253 kW | 10,152.18 lb |

TRACTOR CONNECTION

3 point hitch cat. III^

FRAME

Reinforced beam 3.15x1.37 in.

Tires 500/50-17

Anti-shock system with nitrogen accumulator on transport wheel

Parking stand

ADJUSTMENTS

Working width adjustable mechanically (PASSO) or hydraulically (VARIO)

1st body mechanic adjustment

Mechanical adjustment of working depth

Mechanical true line adjustment

SAFETY SYSTEM

Shear bolt safety system

Wheel with hydropneumatics shock absorber for transport

WORKING BODIES

Moldboard MP4WN

Tungsten share point on each moldboard

Reinforced skimmers supports

Coulter knife on the last body

| Measure | No. of bodies | Bodies working width | Inter-body clearance | Under beam clearance STD | Power required HP | Power required KW | Weight |

|---|---|---|---|---|---|---|---|

| 6+0 | 6 | 13.8-15.7-17.7-19.7-21.7 in | 41.34 in | 31.5 in | 220-260 hp | 164-194 kW | 8,708.17 lb |

| 7+0 | 7 | 13.8-15.7-17.7-19.7-21.7 in | 41.34 in | 31.5 in | 260-300 hp | 194-224 kW | 9,534.9 lb |

| Measure | No. of bodies | Bodies working width | Inter-body clearance | Under beam clearance STD | Power required HP | Power required KW | Weight |

|---|---|---|---|---|---|---|---|

| 6+0 | 6 | 11.8-21.7 in | 41.34 in | 31.5 in | 220-260 hp | 164-194 kW | 8,994.77 lb |

| 7+0 | 7 | 11.8-21.7 in | 41.34 in | 31.5 in | 260-300 hp | 194-224 kW | 9,898.65 lb |

TRACTOR CONNECTION

3 point hitch cat. III^

FRAME

Reinforced beam 3.15x1.37 in.

Tires 500/50-17

Anti-shock system with nitrogen accumulator on transport wheel

Parking stand

ADJUSTMENTS

Working width adjustable mechanically (PASSO) or hydraulically (VARIO)

1st body mechanic adjustment

Mechanical adjustment of working depth

SAFETY SYSTEM

NON STOP hydraulic safety system

Wheel with hydropneumatics shock absorber for transport

WORKING BODIES

Moldboard MP4WN

Tungsten share point on each moldboard

Reinforced skimmers supports

Coulter knife on the last body