Mounted sprayer

MASCHIO GASPARDO presents the new top of the range mounted spreader TEMPO ULTRA ISOTRONIC, which combines high functional efficiency, precision and comfortable use regardless of the soil conditions. Universal machine with professional functional features, it is suitable for medium and large-sized farms, ensuring low running costs.

The high distribution quality is among the decisive factors to ensure performance, effectiveness in crop protection and respect for the environment, aspects that meet the needs of the most attentive sector professionals.

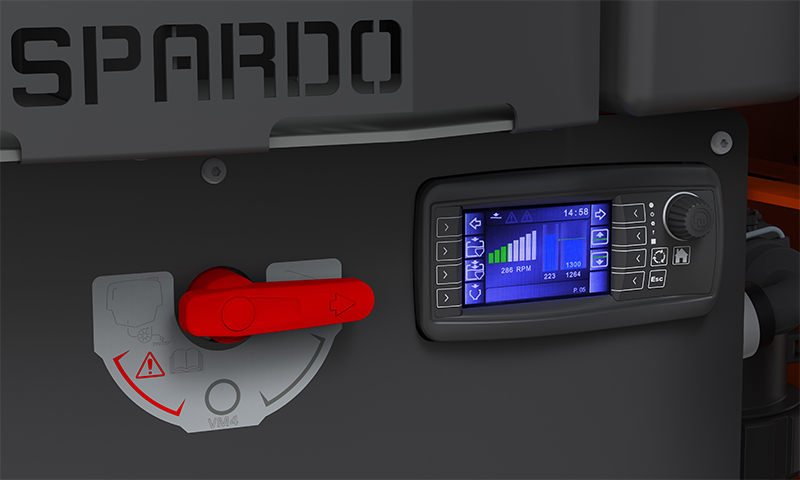

TEMPO ULTRA ISOTRONIC has been designed by GASPARDO engineers with the intention of introducing a newly-designed sprayer. The frame is integrated into the new design of 1,600 and 2,000 L tanks, improving overall ergonomics and comfort of use. The use of vibration damper systems made with innovative materials, helps reduce dynamic stresses in the structural parts, ensuring high mechanical resistance to stress and wear. ISOTRONIC system with ISOBUS communication protocol allows the use of the Precision Farming functions.

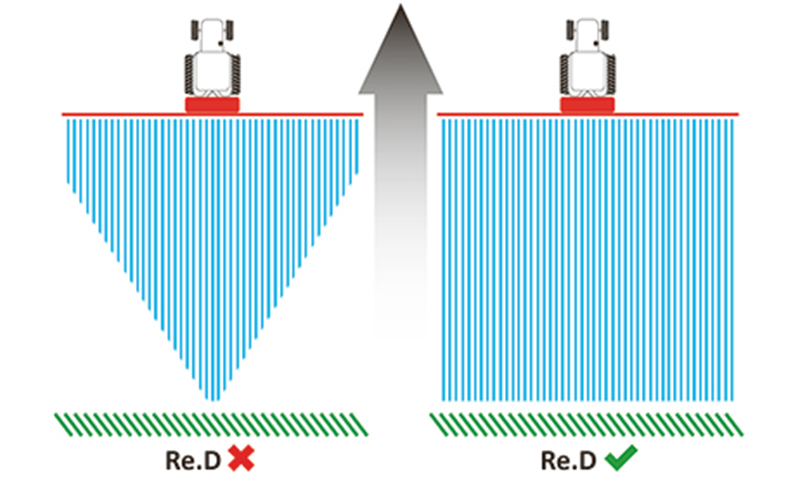

Spraying carried out by large equipment requires precise and efficient management systems for the distribution of plant protection products. Re.D is the semi-active recirculation system of the product used in MASCHIO GASPARDO sprayers which avoids activation delays and consequent untreated areas when activating and shutting down the spreading sections. The water circuit is managed from the machine panel which can be manual (M-PANEL) or electronic (E-PANEL) with valves electro-actuated via the machine monitor or virtual terminal in the tractor cab.

Low weight, high structural strength due to the use of high-strength steels and safety system to counteract yaw oscillations give “ALA 400” boom maximum functional reliability over time. The “Z” closure of ALA 400 provides a low total width with a transport width of only 2.4 m in order to comply with the regulations in force in terms of road circulation even in the 28 m work width version.

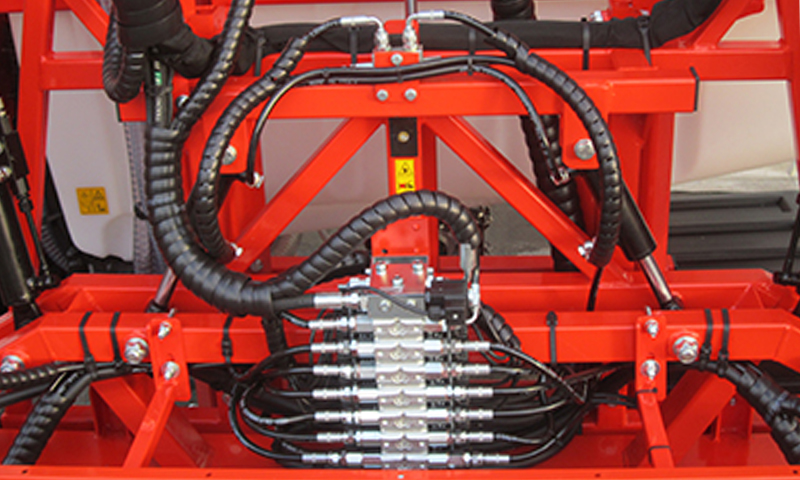

Boom movements are managed by the standard OILDRIVE system. The commands are given from the Virtual Terminal on the tractor or via Joystick (optional accessory). The boom can be assisted by an accessory electronic system to automatically maintain the crop distance, whose operation is based on the use of radar sensors connected to a special control unit that acts on the hydraulic lifting and on the level corrector. This system makes it possible to use the sprayer even on hilly or uneven ground.

| Measure | Real tank capacity | Boom width | N. of sections | Circuit rinse tank capacity | Pump type | Control group | Hitch | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 1300 | 383.09 gal | 49.21 ft | 5 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 2,976.21 lb |

| 1300 | 383.09 gal | 59.05 ft | 7 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 2,821.89 lb |

| 1600 | 480.84 gal | 49.21 ft | 5 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,130.53 lb |

| 1600 | 480.84 gal | 59.05 ft | 7 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 2,865.98 lb |

| 2000 | 575.96 gal | 49.21 ft | 5 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 2,865.98 lb |

| 2000 | 575.96 gal | 59.05 ft | 7 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 2,976.21 lb |

| Measure | Real tank capacity | Boom width | N. of sections | Circuit rinse tank capacity | Pump type | Control group | Hitch | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 1300 | 383.09 gal | 39.37 ft | 5 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 0 lb |

| 1300 | 383.09 gal | 49.21 ft | 5 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,461.22 lb |

| 1300 | 383.09 gal | 52.49 ft | 5 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,968.28 lb |

| 1300 | 383.09 gal | 59.05 ft | 5 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,527.36 lb |

| 1300 | 383.09 gal | 65.62 ft | 7 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,968.28 lb |

| 1300 | 383.09 gal | 68.9 ft | 7 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,637.59 lb |

| 1300 | 383.09 gal | 78.74 ft | 7 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,968.28 lb |

| 1300 | 383.09 gal | 88.58 ft | 9 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,968.28 lb |

| 1300 | 383.09 gal | 91.86 ft | 9 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,968.28 lb |

| 1300 | 383.09 gal | 98.42 ft | 9 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,968.28 lb |

| 1600 | 480.84 gal | 39.37 ft | 5 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,968.28 lb |

| 1600 | 480.84 gal | 49.21 ft | 5 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,527.36 lb |

| 1600 | 480.84 gal | 52.49 ft | 5 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,968.28 lb |

| 1600 | 480.84 gal | 59.05 ft | 5 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,527.36 lb |

| 1600 | 480.84 gal | 65.62 ft | 7 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,968.28 lb |

| 1600 | 480.84 gal | 68.9 ft | 7 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,791.91 lb |

| 1600 | 480.84 gal | 78.74 ft | 7 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,924.19 lb |

| 1600 | 480.84 gal | 88.58 ft | 9 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,924.19 lb |

| 1600 | 480.84 gal | 91.86 ft | 9 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,924.19 lb |

| 1600 | 480.84 gal | 98.42 ft | 9 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 4,298.97 lb |

| 2000 | 575.96 gal | 39.37 ft | 5 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,968.28 lb |

| 2000 | 575.96 gal | 49.21 ft | 5 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,527.36 lb |

| 2000 | 575.96 gal | 52.49 ft | 5 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,968.28 lb |

| 2000 | 575.96 gal | 59.05 ft | 5 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,527.36 lb |

| 2000 | 575.96 gal | 65.62 ft | 7 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 3,968.28 lb |

| 2000 | 575.96 gal | 68.9 ft | 7 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 4,012.37 lb |

| 2000 | 575.96 gal | 78.74 ft | 7 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 4,012.37 lb |

| 2000 | 575.96 gal | 88.58 ft | 9 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 4,012.37 lb |

| 2000 | 575.96 gal | 91.86 ft | 9 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 4,012.37 lb |

| 2000 | 575.96 gal | 98.42 ft | 9 | 79.26 gal | BPS 200 | ISOBUS | 3 point cat. II^N | 88 kW | 4,409.2 lb |

FRAME

Cataphoresis painted monobloc frame with stabilizing feet

3 point quick hitch lifter

Integrated folding ladder

TANK GROUP

Total emptying polyethylene tank

Circuit rinse tank with connections and rinse tank rotating jet

Hinged lid with bayonet joint

Handwashing tank

Integrated main and wash circuit level indicators

FILLING AND FILTERING

M-PANEL: manual panel on the left side with centralized controls, integrated and protected

3 way deviator for tank filling

2" camlock quick hitch for filling from external non-pressurized source

Inspectionable external suction filter

External selfcleaning supply filter

Triple hydraulic agitation through perforated tube, pressure agitators and hydrojectors

Pre-mixer with anti-stagnation flow and gun

Flowback: advanced anti-drip system

PUMP

Comet pump

Flow pump control kit for functional testing

PTO shaft (tractor side yoke 1" 3/8 Z6)

COMMAND GROUP

ISOBUS control unit compliant with ISO standard ISO 11783

Speed sensor on the tractor wheel

Pressure sensor

Flowmeter

Differential pressure gauge integrated into the frame

WORK U BOOM

Cataphoresis painted boom

Painted bar in cataphoresis and powders

Independent opening and closing of the arms

Independent opening and closing of the tips

Self-leveling and hydraulic locking

Rear led lights bar

Sliding protections

Trijet without nozzles

OILDRIVE 7 - 1 pair of quick hitches on the tractor needed

ALA 400 BOOM

Painted bar in cataphoresis and powders

Hydraulic lifting at 59.06 in.,double hydropneumatic shock absorber

Overlapping sequential opening and closing of the arms, right and left independent

Self-leveling and hydraulic locking

Variable geometry

Rear led lights bar

Trijet without nozzles

OILDRIVE 7 - 1 pair of quick hitches on the tractor needed