Variable chamber round baler with electronic variable geometry and 4 belts

EXTREME 3 is the variable chamber and geometry round baler, combining high performance with utmost care in crop harvesting. The double rocker system, managing the chamber and variable geometry with pressure up to 3,046 psi (210 bar), allows you to harvest any type of crop at any moisture level for optimal storage.

Exceptional durability, high working capacity, perfectly formed, compact bales weighing up to approximately 364 lbs and measuring up to 65 inches in diameter make EXTREME 3 a profitable investment—especially thanks to the option to equip it with three different feeding systems.

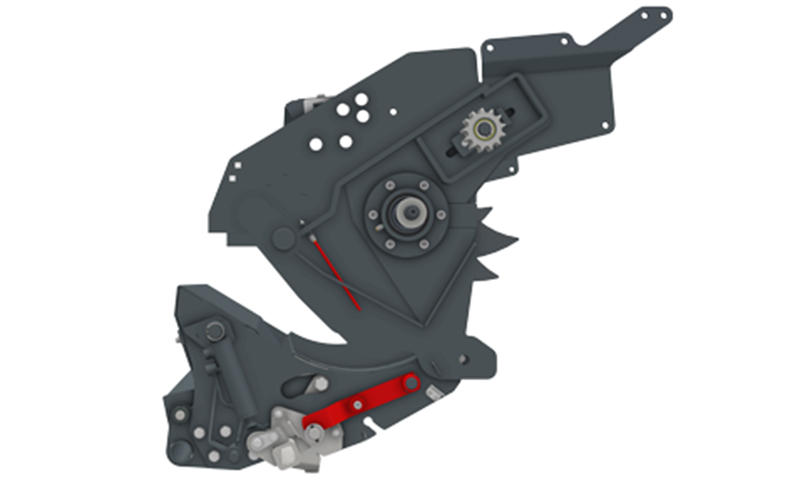

The variable chamber is managed by a double rocker controlled by hydraulic cylinders. The first rocker defines the pressure and bale diameter, allowing the creation of a zero-pressure pre-chamber up to 35 inches, while the second rocker automatically compensates the tension of the four ENDLESS belts during bale formation. This ensures significant benefits for those who prioritize product quality.

The large 86.6-inch pick-up with fixed wheels allows operation even with windrows that are not perfectly uniform and abundant. The forage is collected gently regardless of the type, even with leafy crops. The machine comes standard equipped with a windrow press roller.

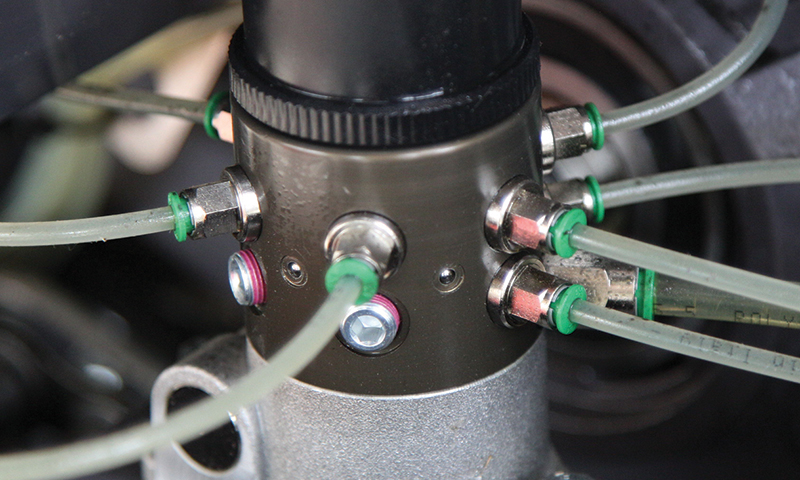

To meet the demands of contractors who subject the baler to prolonged heavy use, the EXTREME 3 is equipped with reinforced 1¼-inch chains capable of withstanding the toughest stresses. The automatic chain lubrication system ensures the machine remains well-lubricated and performs reliably at all times.

EXTREME Series 3 is versatile, offering 3 selectable feeding systems: HTR rotary feeder, HTC rotary feeder with 15 knives, and HTU rotary feeder with 25 knives. The stars of all rotors are made of high-strength HARDOX steel to minimize wear during operation.

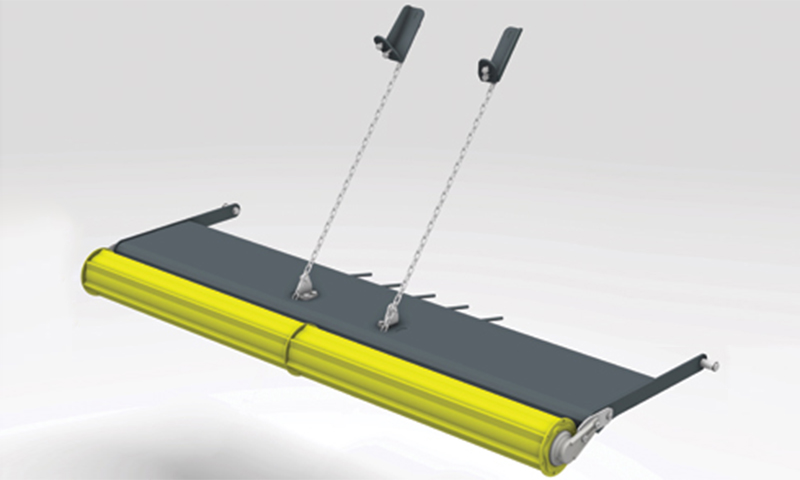

Designed for true professionals, the EXTREME 3 is equipped with 4 ENDLESS belts, ensuring optimal durability in all conditions, even at high pressures and speeds. Covering the entire width of the bale during formation helps reduce product loss and preserve quality. The two motorized rollers guarantee perfect belt rotation even with very wet material.

EXTREME 3 ISOTRONIC is the latest generation version, updated with the ISOBUS communication protocol. All working parameters can be easily and intuitively managed from the ISOBUS terminal in the tractor. This advanced equipment is perfect both for forage farms and the most demanding contractors.

Designed for true professionals, EXTREME 3 combines robustness and high-quality pressing performance up to 3,045 psi (210 bar) in a single piece of equipment. The variable chamber, which also allows creating a zero-pressure pre-chamber, enables harvesting different types of crops with varying moisture levels, always ensuring optimal results. The ENDLESS belts help guarantee a long service life for this machine.

| Measure | Ø bale (min) | Ø bale (max) | Bale width | Pick-up width | Belts type | No. of belts | Tying | Wheels | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 365 HTR | 1.64 ft | 5.41 ft | 3.94 ft | 7.22 ft | Endless | 4 | Net | 400/60-15.5 | 70 kW | 7,649.96 lb |

| Measure | Ø bale (min) | Ø bale (max) | Bale width | Pick-up width | Belts type | No. of belts | Tying | Wheels | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 365 HTC | 1.64 ft | 5.41 ft | 3.94 ft | 7.22 ft | Endless | 4 | Net | 400/60-15.5 | 79 kW | 7,826.33 lb |

| Measure | Ø bale (min) | Ø bale (max) | Bale width | Pick-up width | Belts type | No. of belts | Tying | Wheels | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 365 HTU | 1.64 ft | 5.41 ft | 3.94 ft | 7.22 ft | Endless | 4 | Net | 400/60-15.5 | 79 kW | 8,062.22 lb |

TRANSMISSION

Wide angle cam-shaft

PTO 540 rpm

CONTROL GROUP

Multifunction electronic control unit ICON

FEEDING SYSTEM

Pick-up 86.61 in with 4 tooth bars with fixed wheels and crop roller

Rotor TOPCUT: 15 knives, cutting length 3.03 in. (version HTC)

Rotor (version HTR)

Rotor ULTRACUT: 25 knives, cutting length 1.77 in. (version HTU)

Drop floor

|BALE COMPRESSION SYSTEM

Variable chamber with pre-starting chamber

Electronic variable geometry

Hydraulic bale compression with electronic density adjustment

4 endless closed-loop belts with width 109.06 in.

TYING SYSTEM

Net tying system

Net stock compartment

LUBRIFICATION

Automatic chain and pick-up lubrication

Manual centralized greasing system

FRAME

Adjustable axle

Couple of shrinking cups

Pick-up support chains

Ladder

LED road lights

Tires 400/60-15,5

Mother Regulation road homologation available without braking system

| Measure | Ø bale (min) | Ø bale (max) | Bale width | Pick-up width | Belts type | No. of belts | Tying | Wheels | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 365 HTR | 1.64 ft | 5.41 ft | 3.94 ft | 7.22 ft | Endless | 4 | Net | 400/60-15.5 | 70 kW | 7,649.96 lb |

| Measure | Ø bale (min) | Ø bale (max) | Bale width | Pick-up width | Belts type | No. of belts | Tying | Wheels | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 365 HTC | 1.64 ft | 5.41 ft | 3.94 ft | 7.22 ft | Endless | 4 | Net | 400/60-15.5 | 79 kW | 7,826.33 lb |

| Measure | Ø bale (min) | Ø bale (max) | Bale width | Pick-up width | Belts type | No. of belts | Tying | Wheels | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|---|

| 365 HTU | 1.64 ft | 5.41 ft | 3.94 ft | 7.22 ft | Endless | 4 | Net | 400/60-15.5 | 79 kW | 8,062.22 lb |

TRANSMISSION

Wide angle cam-shaft

PTO 540 rpm

CONTROL GROUP

Complies with ISO 11783 standard

FEEDING SYSTEM

Pick-up 86.61 in with 4 tooth bars with fixed wheels and crop roller

Rotor TOPCUT: 15 knives, cutting length 3.03 in. (version HTC)

Rotor (version HTR)

Rotor ULTRACUT: 25 knives, cutting length 1.77 in. (version HTU)

Drop floor

BALE COMPRESSION SYSTEM

Variable chamber with pre-starting chamber

Electronic variable geometry

Hydraulic bale compression with electronic density adjustment

4 endless closed-loop belts with width 109.06 in.

TYING SYSTEM

Net tying system

Net stock compartment

LUBRIFICATION

Automatic chain and pick-up lubrication

Manual centralized greasing system

FRAME

Adjustable axle

Couple of shrinking cups

Pick-up support chains

Ladder

LED road lights

Tires 400/60-15,5

Mother Regulation road homologation available without braking system