Mounted teuton mistblower

TURBO TEUTON P POLIPO was created from the need to ensure high treatment efficiency with great attention to the environment, minimising the pollution diffused by the distribution of plant protection products. This is made possible thanks to the localised diffusion system and the high coverage capacity of the treatment through the production and atomised distribution of micro drops. TURBO TEUTON system is ideal for the treatment of crops with irregular leaf walls or in which covering treatments are privileged.

The mounted mistblowers are subjected to strong vibrations and structural stress. The continuous movement of the liquid creates continuous inertia especially in hilly environments where vineyards and orchards are often located, situations that greatly stress the tank and the frames. For this reason, the construction components and materials used have been carefully studied to ensure sturdiness and low maintenance over time. The frame, made of high-strength steel, also ensures high corrosion resistance thanks to the hot-dip galvanisation treatment, while the high density polyethylene tanks ensure structural strength, low weight and high resistance to UV rays.

Maximum treatment effectiveness is achieved thanks to the low volume dispensing system and the type of air conveyors that localise the flow on the surface to be treated. The low volume dispensed is obtained thanks to the combined action of mechanical pulverisation of the phytoiatric product flow through the high pressure pump and the particular nozzle used and pneumatic pulverisation carried out by the fan/diffuser assembly. In addition to directing the flow in the desired direction, the air conveyors ensure greater control of the treatment height also thanks to the possibility of excluding the individual nozzles. To increase treatment coverage and further reduce the risk of diffused pollution, the ELECTROSTATIC kit is available on request which, thanks to the electrodes placed at the air diffuser outlet, positively charges the droplets of the phytoiatric product flow so that they are attracted to vegetation naturally provided with negative charges.

TURBO TEUTON P POLIPO is also available in ISOTRONIC version with ISOBUS communication protocol. Thanks to the combination with the tractor’s Virtual Terminal or with different Virtual Terminals available upon request, sprayer management is simpler and more intelligent both in terms of precision farming and greater control of the functional parameters used in the field.

TURBOTEUTON P POLIPO exploits the advantages of a solid but lightweight frame together with the mixed spraying system that reduces volumes without increasing the risk of drift.

| Measure | Real tank capacity | Fan diameter | N. of blades | Circuit rinse tank capacity | Pump type | Control group | Hitch | Weight |

|---|---|---|---|---|---|---|---|---|

| 300 | 86.92 gal | 19.31 in | 16 | 7.93 gal | IDS 960 | GCPE 2 WAYS | 3 point cat. I^ | 826.73 lb |

| 400 | 111.76 gal | 19.31 in | 16 | 11.89 gal | IDS 960 | GCPE 2 WAYS | 3 point cat. I^ | 914.91 lb |

| 600 | 167.5 gal | 19.31 in | 16 | 11.89 gal | IDS 960 | GCPE 2 WAYS | 3 point cat. II^N | 925.93 lb |

FRAME

Hot dip galvanized frame

Bumper protection

TANK GROUP

Facilitated polyethylene tank emptying

Hinged lid with bayonet joint

Washing circuit system with independent tank (measure 600)

1 rotating tank jet (measure 600)

Handwashing tank

FILLING AND FILTERING

External inspectionable suction filter with tank filling connection

Pressure agitator

Hydraulic agitator with perforated tube

DEVIOKIT: circuit rinse system even with full tank (measure 600)

PUMP

Comet pump

COMMAND GROUP

2 ways electric pressure regulator

Control panel for water section management

2 manual valves for agitation and cleaning

Differential pressure gauge

FAN UNIT

Apparatus 8 dispensers:

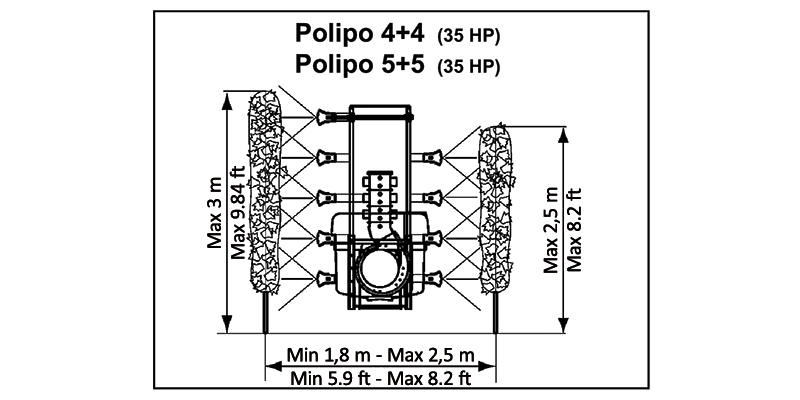

Dispensers for row-spacing 5.9 ft - 13.12 ft

Rear suction fan group

Painted conveyor and centrifugal rotor

Double anti-drip brass jets with quick shut-off with nozzles

Nozzles:

• HCI 80-01 orange ceramic

• HCI 80-02 yellow ceramic

2-speed gearbox + neutral, with easy oil filling

| Measure | Real tank capacity | Fan diameter | N. of blades | Circuit rinse tank capacity | Pump type | Control group | Hitch | Weight |

|---|---|---|---|---|---|---|---|---|

| 300 | 86.92 gal | 19.31 in | 16 | 7.93 gal | IDS 960 | ISOBUS | 3 point cat. I^ | 837.75 lb |

| 400 | 111.76 gal | 19.31 in | - | 11.89 gal | IDS 960 | ISOBUS | 3 point cat. I^ | 881.84 lb |

| 600 | 167.5 gal | 19.31 in | 16 | 11.89 gal | IDS 960 | ISOBUS | 3 point cat. II^N | 925.93 lb |

FRAME

Hot dip galvanized frame

Bumper protection

TANK GROUP

Facilitated polyethylene tank emptying

Hinged lid with bayonet joint

Washing circuit system with independent tank (measure 600)

1 rotating tank jet (measure 600)

Handwashing tank

FILLING AND FILTERING

External inspectionable suction filter with tank filling connection

Pressure agitator

Hydraulic agitator with perforated tube

DEVIOKIT: circuit rinse system even with full tank (measure 600)

PUMP

Comet pump

COMMAND GROUP

ISOBUS control unit compliant with ISO standard ISO 11783

2-way electric solenoid pressure regulator

Pressure sensor

Flowmeter

2 manual valves for agitation and cleaning

Differential pressure gauge

FAN UNIT

Appratus 8 dispensers:

Dispensers for row-spacing 5.9 ft - 13.12 ft

Rear suction fan group

Painted conveyor and centrifugal rotor

Double anti-drip brass jets with quick shut-off with nozzles

Nozzles:

HCI 80-01 orange ceramic

HCI 80-02 yellow ceramic

2-speed gearbox + neutral, with easy oil filling