Mounted plough with parallelogram adjustment and shear bolt safety system

Designed for in furrow ploughing, UNICO M has multiple working position correction and safety systems to handle the combined tasks of soil aeration, crop residue burial and incorporation. Doing away with welded joints between the frame and plough bodies in favour of bolting ensures strength, reliability and stability even under considerable stress. Available in an up to 5 bodies configuration, it is suitable for tractors with horsepower up to 200 HP.

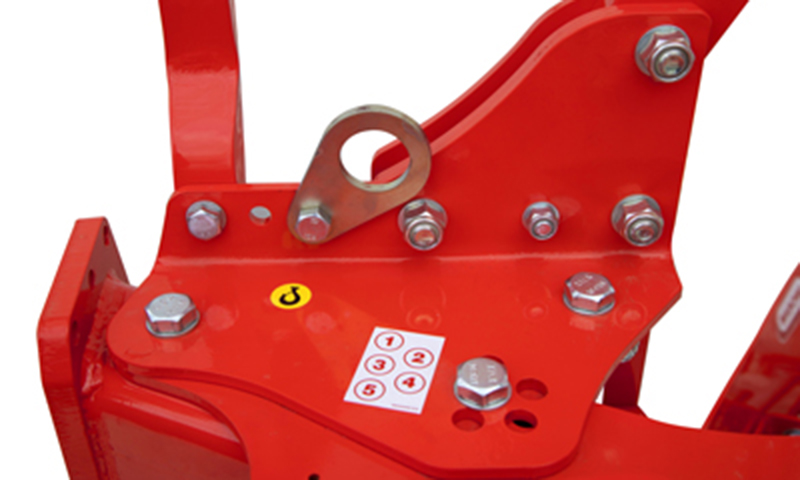

The modular design means a standard frame built to accommodate three or four plough bodies, with the option of attaching an additional body using a bolted-on connection plate (standard issue on extendible versions), meaning coupling can be done in a matter of seconds. The headstock also allows for different types of configuration. The upper hitch point and rotation pin are part of a central housing that is an integral part of the plough, while the lower hitch points feature bolt-on removable flanged fixings, offering a number of advantages: switching quickly from the fixed headstock configuration to an oscillating one or to different category hitches in a matter of seconds and, lastly, being able to change the height of the connection to the lift to accommodate tractors with different wheels sizes.

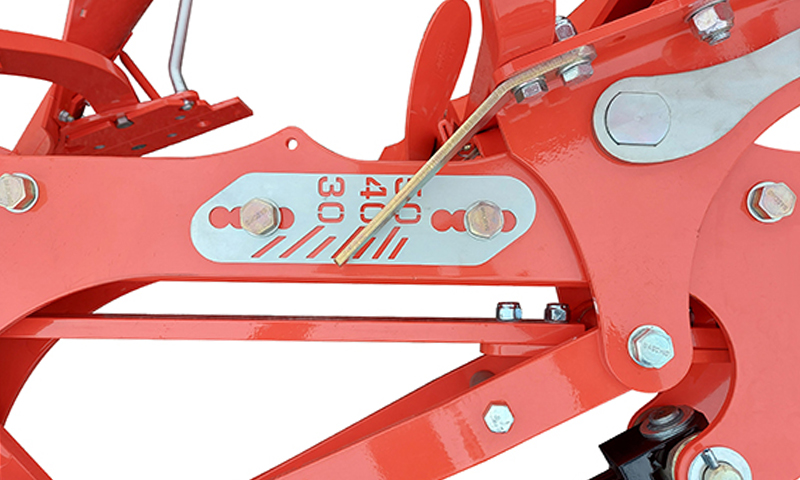

UNICO M features the "SMOOTH SET" parallelogram system, designed to optimise true line and first body working width adjustment setup times and improve the accuracy of work in the field. This system means that, on the one hand, there is less stress on the frame and headstock and, on the other, the true line and first body width adjustments are not affected by changes to the working width.

Working width can be mechanically adjusted by means of the STEP-BY-STEP type, PASSO system, which has 5 bolt position options for locking in the most suitable setup in just a few steps. Alternatively, the VARIO version features a non-stop adjustment system. Working width is changed by means of a hydraulic cylinder by suitably adjusting hydraulic power unit's relevant controls.

All 4+0 versions (extendible 4-bodies models) come with the automatic frame alignment memory, which allows the weight of the plough to be centred over the pivot shaft during turnover, thus reducing stress on tractor's lift arms, as well as preventing it from hitting the ground during turnover, which is particularly important when dealing with 5-bodies versions.

In addition to the classic shear bolt system, there is the option of the NSH version with Non-Stop Hydraulic safety system. Hydraulic cylinders connected to the rear of each plough body - with a pre-charge that can be hydraulically adjusted from the cab - enable the bodies in question to be lifted in the event of impact, returning them to the right position as soon as they have cleared the obstacle. Given their working position behind the wheels of the tractor, the first and fourth plough bodies have larger-bore cylinders to withstand a higher load, considering the more compacted soil they have to work.

The wide range of available configurations makes the UNICO M plough extremely versatile for use with medium power tractors. The NSH version with hydraulic No Stop system allows safe and effective ploughing.

| Measure | No. of bodies | Bodies working width | Inter-body clearance | Headstock diameter | Under beam clearance STD | Hitch | Power required HP | Power required KW | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 3+0 | 3 | 11.8-13.8-15.7-17.7-19.7 in | 37.4 in | 3.94 in | 31.5 in | 3 point cat. II^ | 90-110 hp | 67-82 kW | 2,380.97 lb |

| 3+0 | 3 | 13.0-15.0-17.3-19.7-21.7 in | 41.34 in | 3.94 in | 31.5 in | 3 point cat. II^ | 90-110 hp | 67-82 kW | 2,398.6 lb |

| 4+0 | 4 | 11.8-13.8-15.7-17.7-19.7 in | 37.4 in | 4.73 in | 31.5 in | 3 point cat. III^ | 119-139 hp | 89-104 kW | 3,209.9 lb |

| 4+0 | 4 | 13.0-15.0-17.3-19.7-21.7 in | 41.34 in | 4.73 in | 31.5 in | 3 point cat. III^ | 119-139 hp | 89-104 kW | 3,214.31 lb |

| Measure | No. of bodies | Bodies working width | Inter-body clearance | Headstock diameter | Under beam clearance STD | Hitch | Power required HP | Power required KW | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 3+0 | 3 | 11.8-21.7 in | 37.4 in | 3.94 in | 31.5 in | 3 point cat. II^ | 90-110 hp | 67-82 kW | 2,546.31 lb |

| 3+0 | 3 | 11.8-21.7 in | 41.34 in | 3.94 in | 31.5 in | 3 point cat. II^ | 90-110 hp | 67-82 kW | 2,583.79 lb |

| 4+0 | 4 | 11.8-21.7 in | 37.4 in | 4.73 in | 31.5 in | 3 point cat. III^ | 119-139 hp | 89-104 kW | 3,417.13 lb |

| 4+0 | 4 | 11.8-21.7 in | 41.34 in | 4.73 in | 31.5 in | 3 point cat. III^ | 119-139 hp | 89-104 kW | 3,443.59 lb |

TRACTOR CONNECTION

3 point hitch cat. II^ (up to 4 bodies and Ø3.94 in headstock)

3 point hitch cat. III^N (from 4+0 bodies and Ø4.72 in headstock)

FRAME

Parallelogram adjustment

Plate for supplementary body

Packer arm flange

Parking stand

ADJUSTMENTS

Working width adjustable mechanically (PASSO) or hydraulically (VARIO)

Frame alignment automatic memory with 1st body mechanic adjustment (for versions starting from 4+0)

Mechanical true line adjustment

SAFETY SYSTEM

Shear bolt safety system

WORKING BODIES

Moldboard MP4WN

Share point on each moldboard

Coulter knife on the last body

| Measure | No. of bodies | Bodies working width | Inter-body clearance | Headstock diameter | Under beam clearance STD | Hitch | Power required HP | Power required KW | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 3+0 | 3 | 11.8-13.8-15.7-17.7 in | 37.4 in | 3.94 in | 31.5 in | 3 point cat. II^ | 90-110 hp | 67-82 kW | 2,711.66 lb |

| 4+0 | 4 | 11.8-13.8-15.7-17.7 in | 37.4 in | 4.73 in | 31.5 in | 3 point cat. III^ | 119-139 hp | 89-104 kW | 3,730.18 lb |

| Measure | No. of bodies | Bodies working width | Inter-body clearance | Headstock diameter | Under beam clearance STD | Hitch | Power required HP | Power required KW | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 3+0 | 3 | 11.8-21.7 in | 37.4 in | 3.94 in | 31.5 in | 3 point cat. II^ | 90-110 hp | 67-82 kW | 2,910.07 lb |

| 4+0 | 4 | 11.8-21.7 in | 37.4 in | 4.73 in | 31.5 in | 3 point cat. III^ | 119-139 hp | 89-104 kW | 3,924.19 lb |

TRACTOR CONNECTION

3 point hitch cat. II^ (up to 4 bodies and Ø3.94 in headstock)

3 point hitch cat. III^N (from 4+0 bodies and Ø4.72 in headstock)

FRAME

Parallelogram adjustment

Plate for supplementary body

Packer arm flange

Parking stand

ADJUSTMENTS

Working width adjustable mechanically (PASSO) or hydraulically (VARIO)

Frame alignment automatic memory with 1st body mechanic adjustment (for versions starting from 4+0)

Mechanical true line adjustment

SAFETY SYSTEM

NON STOP hydraulic safety system

Oversized cylinder bore on 1st and 4th body NON STOP

WORKING BODIES

Moldboard MP4WN

Share point on each moldboard

Coulter knife on the last body