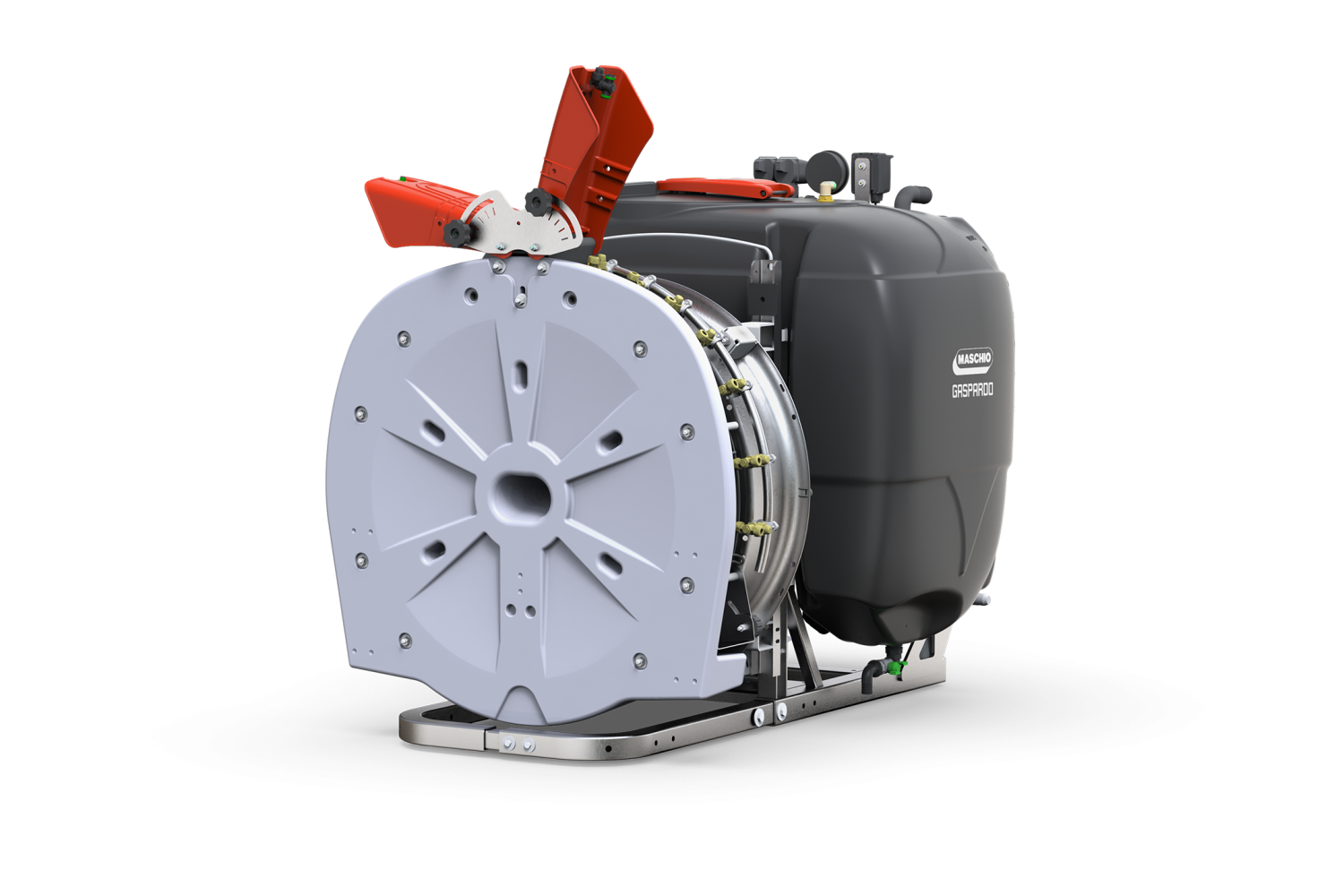

Mounted axial-fan mistblower

EXPO introduces the segment of MASCHIO GASPARDO mounted mistblowers. Characterised by a compact design and a remarkable lightness, EXPO is ideal for working very narrow row or canopy crops. The tank capacity of up to 600 L in combination with the different types of fans available, which ensure the product is efficiently transported up to the area to be treated, always make it possible to find the most suitable solution to your needs.

The mounted mistblowers are subjected to strong vibrations and structural stress. The continuous movement of the liquid creates continuous inertia especially in hilly environments where vineyards and orchards are often located, situations that greatly stress the tank and the frames. For this reason, the construction components and materials used have been carefully studied to ensure sturdiness and low maintenance over time. The high-strength steel frame ensures high corrosion resistance thanks to the hot-dip galvanisation treatment. The high density polyethylene tanks ensure structural strength, low weight and high resistance to UV rays.

EXPO can be combined with a wide range of nozzles, including some anti-drift. In the latter, air is injected during the spraying of the mixture, weighing down the droplets formed and minimising the possibility of being carried away by the wind. To increase treatment coverage and further reduce the risk of diffused pollution, the ELECTROSTATIC kit is available on request which, thanks to the electrodes placed at the air diffuser outlet, positively charges the droplets of the phytoiatric product flow so that they are attracted to vegetation naturally provided with negative charges.

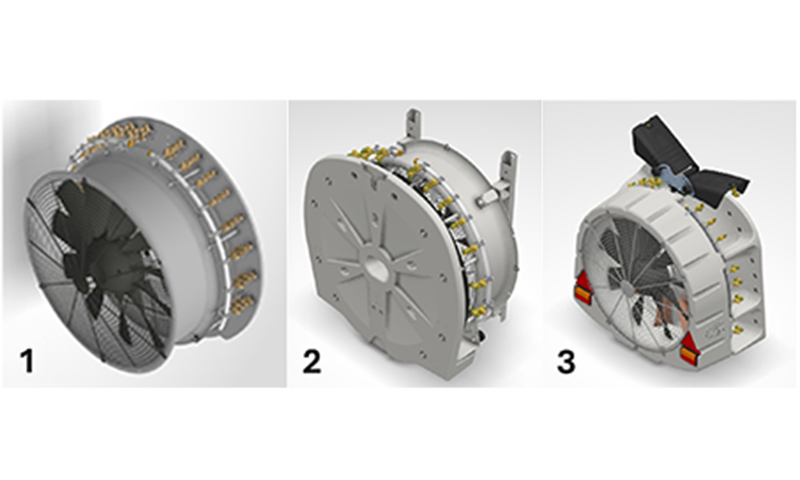

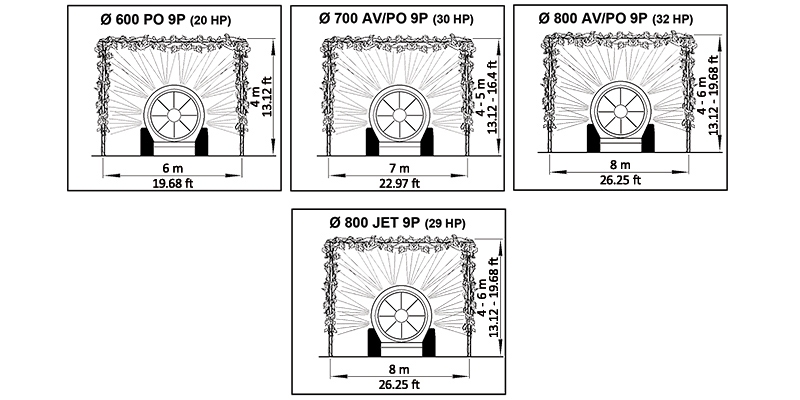

EXPO can be equipped with three different fan units: AVANT with front suction, POST and JET with rear suction, the latter with a plastic structure. This wide choice makes it possible to adapt mistblower to different conditions and types of crops. Different electric control units are available on request to ensure greater operator comfort and safety, which allow a total functional control from the machine or directly from the tractor cab.

| Measure | Real tank capacity | Fan diameter | N. of blades | Circuit rinse tank capacity | Pump type | Control group | Hitch | Weight |

|---|---|---|---|---|---|---|---|---|

| 300 | 86.92 gal | 23.64 in | 9 | 0 gal | APS 51 | RVC 2 WAYS | 3 point cat. I^ | 485.01 lb |

| 300 | 86.92 gal | 27.58 in | 9 | 0 gal | APS 71 | RVC 2 WAYS | 3 point cat. I^ | 562.17 lb |

| 400 | 111.76 gal | 23.64 in | 9 | 0 gal | APS 51 | RVC 2 WAYS | 3 point cat. I^ | 469.58 lb |

| 400 | 111.76 gal | 27.58 in | 9 | 0 gal | APS 71 | RVC 2 WAYS | 3 point cat. I^ | 595.24 lb |

| 600 | 167.5 gal | 27.58 in | 9 | 11.89 gal | APS 71 | RVC 2 WAYS | 3 point cat. II^N | 705.47 lb |

| Measure | Real tank capacity | Fan diameter | N. of blades | Circuit rinse tank capacity | Pump type | Control group | Hitch | Weight |

|---|---|---|---|---|---|---|---|---|

| 300 | 86.92 gal | 27.58 in | 9 | 0 gal | APS 71 | RVC 2 WAYS | 3 point cat. I^ | 573.2 lb |

| 400 | 111.76 gal | 27.58 in | 9 | 0 gal | APS 71 | RVC 2 WAYS | 3 point cat. I^ | 639.33 lb |

| 400 | 111.76 gal | 31.52 in | 9 | 0 gal | APS 96 | RVC 2 WAYS | 3 point cat. I^ | 661.38 lb |

| 600 | 167.5 gal | 31.52 in | 9 | 11.89 gal | APS 96 | RVC 2 WAYS | 3 point cat. II^N | 749.56 lb |

| Measure | Real tank capacity | Fan diameter | N. of blades | Circuit rinse tank capacity | Pump type | Control group | Hitch | Weight |

|---|---|---|---|---|---|---|---|---|

| 400 | 111.76 gal | 31.52 in | 9 | 0 gal | APS 96 | RVC 2 WAYS | 3 point cat. I^ | 573.2 lb |

| 600 | 167.5 gal | 31.52 in | 9 | 11.89 gal | APS 96 | RVC 2 WAYS | 3 point cat. II^N | 727.52 lb |

FRAME

Hot dip galvanized frame

Bumper protection

TANK GROUP

Facilitated polyethylene tank emptying

Hinged lid with bayonet joint

Washing circuit system with independent tank (measure 600)

1 rotating tank jet (measure 600)

Handwashing tank

TANK GROUP

External inspectionable suction filter with tank filling connection

Pressure agitator

Hydraulic agitator with perforated tube

DEVIOKIT: circuit rinse system even with full tank (measure 600)

PUMP

Comet pump

COMMAND GROUP

2 ways manual pressure regulator

2 manual valves for agitation and cleaning

Differential pressure gauge

FAN UNIT

Impeller with nylon blades adjustable in 3 positions

Top deflectors without jets

Stainless steel rod holders

Double anti-drip brass jets with quick shut-off

Nozzles:

• HCI 60-015 green ceramic

• HCI 60-03 blue ceramic

2-speed gearbox + neutral, with easy oil filling