Mounted sprayer

TEKO sprayer is the answer for farmers looking for a compact, reliable machine with superior range solutions. Available with hydraulic booms and work widths up to 18 m, it can be enhanced with a variety of accessories, offering the customer the most suitable solution for their needs.

TEKO is characterised by applications that make the most of all its potential, such as DEVIOKIT system for washing the circuit, even with the tank full, and GREENMIX T30 pre-mixer. The latter application is essential for reducing the charging down times and the operator exposure to risk.

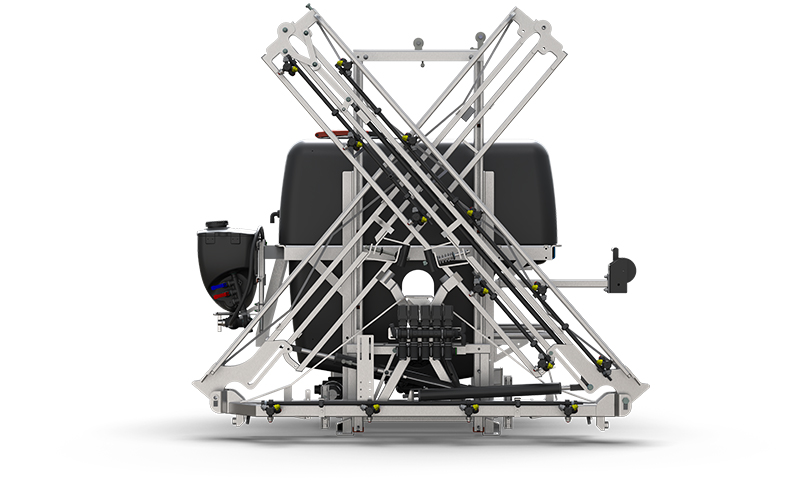

The spraying booms provided for TEKO model are characterised by the wheeled hydraulic lifting. START BOOM with X closure covers 12 and 15 m work widths, while WORK U boom with U closure is available in the 18 m work width version. Both versions are fitted with self-leveller and automatic mechanical lock. OLIDRIVE system, available upon request, makes it possible to centrally control the main boom movements from a special push button panel.

Thanks to the wide range of accessories available, TEKO offers customisations that meet the specific requests of users. From the control assembly (manual, electric or DPAE computerised) to the possibility of making it simpler to use the boom for different spreading conditions thanks to TRIJET nozzle-holder system.

ISOTRONIC version, for the more demanding farmers and contractors, is also available with ISOBUS communication protocol for complete digital control of the equipment. Thanks to the different Universal Terminals available, all water, hydraulic and Precision Farming functions can be easily managed.

| Measure | Real tank capacity | Boom width | N. of sections | Circuit rinse tank capacity | Pump type | Control group | Hitch | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 800 | 227.21 gal | 39.37 ft | 5 | 27.48 gal | BP 125 | REMO | 3 point cat. II^ | 66 kW | 1,410.94 lb |

| 800 | 227.21 gal | 49.21 ft | 5 | 27.48 gal | BP 125 | REMO | 3 point cat. II^ | 66 kW | 1,543.22 lb |

| 1000 | 290.62 gal | 39.37 ft | 5 | 27.48 gal | BP 125 | REMO | 3 point cat. II^ | 66 kW | 1,410.94 lb |

| 1000 | 290.62 gal | 49.21 ft | 5 | 27.48 gal | BP 125 | REMO | 3 point cat. II^ | 66 kW | 1,499.13 lb |

| 1200 | 342.93 gal | 39.37 ft | 5 | 27.48 gal | BP 125 | REMO | 3 point cat. II^ | 66 kW | 1,455.04 lb |

| 1200 | 342.93 gal | 49.21 ft | 5 | 27.48 gal | BP 125 | REMO | 3 point cat. II^ | 66 kW | 1,587.31 lb |

| Measure | Real tank capacity | Boom width | N. of sections | Circuit rinse tank capacity | Pump type | Control group | Hitch | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 800 | 227.21 gal | 49.21 ft | 5 | 27.48 gal | BP 125 | REMO | 3 point cat. II^ | 66 kW | 2,204.6 lb |

| 800 | 227.21 gal | 59.05 ft | 5 | 27.48 gal | BP 125 | REMO | 3 point cat. II^ | 66 kW | 1,873.91 lb |

| 800 | 227.21 gal | 59.05 ft | 7 | 27.48 gal | BP 125 | REMO | 3 point cat. II^ | 66 kW | 1,873.91 lb |

| 1000 | 290.62 gal | 49.21 ft | 5 | 27.48 gal | BP 125 | REMO | 3 point cat. II^ | 66 kW | 2,204.6 lb |

| 1000 | 290.62 gal | 59.05 ft | 5 | 27.48 gal | BP 125 | REMO | 3 point cat. II^ | 66 kW | 1,906.98 lb |

| 1000 | 290.62 gal | 59.05 ft | 7 | 27.48 gal | BP 125 | REMO | 3 point cat. II^ | 66 kW | 1,906.98 lb |

| 1200 | 342.93 gal | 49.21 ft | 5 | 27.48 gal | BP 125 | REMO | 3 point cat. II^ | 66 kW | 2,204.6 lb |

| 1200 | 342.93 gal | 59.05 ft | 5 | 27.48 gal | BP 125 | REMO | 3 point cat. II^ | 66 kW | 2,358.92 lb |

| 1200 | 342.93 gal | 59.05 ft | 7 | 27.48 gal | BP 125 | REMO | 3 point cat. II^ | 66 kW | 2,160.51 lb |

FRAME

Cataphoresis painted frame with stabilizing feet

Ladder

TANK GROUP

Total emptying polyethylene tank

Circuit rinse tank with connections and rinse tank rotating jet

Hinged lid with bayonet joint

Handwashing tank

FILLING AND FILTERING

3 way deviator for tank filling

Inspectionable external suction filter

External selfcleaning supply filter

Double hydraulic agitator through perforated tube and pressure agitators

GreenMix T30 premixer

DEVIOKIT: circuit rinse system even with full tank

PUMP

Comet pump

Flow pump control kit for functional testing

PTO shaft (tractor side yoke 1" 3/8 Z6)

COMMAND GROUP

Electric volumetric pressure regulator

Control panel for managing water functions

2 manual valves for operation and cleaning

Differential pressure gauge

START BOOM

Painted bar in cataphoresis and powders

Hydraulic lifting 39.37 in.

Open/close arms in sequence, right/left independent

Mechanical self-levelling with automatic blockage system

Unijet without nozzles

3 pairs of quick couplings required on the tractor

WORK U BOOM

Painted bar in cataphoresis and powders

Hydraulic lifting 39.37 in., double hydropneumatic shock absorber

Simultaneous opening and closing of the arms

Simultaneous opening and closing of the tips

Mechanical self-levelling with automatic blockage system

Sliding protections

Trijet without nozzles

3 pairs of quick couplings required on the tractor

| Measure | Real tank capacity | Boom width | N. of sections | Circuit rinse tank capacity | Pump type | Control group | Hitch | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 800 | 227.21 gal | 39.37 ft | 5 | 27.48 gal | BP 125 | ISOBUS | 3 point cat. II^ | 66 kW | 1,587.31 lb |

| 800 | 227.21 gal | 49.21 ft | 5 | 27.48 gal | BP 125 | ISOBUS | 3 point cat. II^ | 66 kW | 1,543.22 lb |

| 1000 | 290.62 gal | 39.37 ft | 5 | 27.48 gal | BP 125 | ISOBUS | 3 point cat. II^ | 66 kW | 1,499.13 lb |

| 1000 | 290.62 gal | 49.21 ft | 5 | 27.48 gal | BP 125 | ISOBUS | 3 point cat. II^ | 66 kW | 1,455.04 lb |

| 1200 | 342.93 gal | 39.37 ft | 5 | 27.48 gal | BP 125 | ISOBUS | 3 point cat. II^ | 66 kW | 1,432.99 lb |

| 1200 | 342.93 gal | 49.21 ft | 5 | 27.48 gal | BP 125 | ISOBUS | 3 point cat. II^ | 66 kW | 1,587.31 lb |

| Measure | Real tank capacity | Boom width | N. of sections | Circuit rinse tank capacity | Pump type | Control group | Hitch | Power kW (min) | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 800 | 227.21 gal | 49.21 ft | 5 | 27.48 gal | BP 125 | ISOBUS | 3 point cat. II^ | 66 kW | 2,204.6 lb |

| 800 | 227.21 gal | 59.05 ft | 5 | 27.48 gal | BP 125 | ISOBUS | 3 point cat. II^ | 66 kW | 1,763.68 lb |

| 800 | 227.21 gal | 59.05 ft | 7 | 27.48 gal | BP 125 | ISOBUS | 3 point cat. II^ | 66 kW | 1,763.68 lb |

| 1000 | 290.62 gal | 49.21 ft | 5 | 27.48 gal | BP 125 | ISOBUS | 3 point cat. II^ | 66 kW | 2,204.6 lb |

| 1000 | 290.62 gal | 59.05 ft | 5 | 27.48 gal | BP 125 | ISOBUS | 3 point cat. II^ | 66 kW | 1,763.68 lb |

| 1000 | 290.62 gal | 59.05 ft | 7 | 27.48 gal | BP 125 | ISOBUS | 3 point cat. II^ | 66 kW | 1,763.68 lb |

| 1200 | 342.93 gal | 49.21 ft | 5 | 27.48 gal | BP 125 | ISOBUS | 3 point cat. II^ | 66 kW | 2,204.6 lb |

| 1200 | 342.93 gal | 59.05 ft | 5 | 27.48 gal | BP 125 | ISOBUS | 3 point cat. II^ | 66 kW | 1,763.68 lb |

| 1200 | 342.93 gal | 59.05 ft | 7 | 27.48 gal | BP 125 | ISOBUS | 3 point cat. II^ | 66 kW | 2,116.42 lb |

FRAME

Cataphoresis painted frame with stabilizing feet

Ladder

TANK GROUP

Total emptying polyethylene tank

Circuit rinse tank with connections and rinse tank rotating jet

Hinged lid with bayonet joint

Handwashing tank

FILLING AND FILTERING

3 way deviator for tank filling

Inspectionable external suction filter

External selfcleaning supply filter

Double hydraulic agitator through perforated tube and pressure agitators

GreenMix T30 premixer

DEVIOKIT: circuit rinse system even with full tank

PUMP

Comet pump

Flow pump control kit for functional testing

PTO shaft (tractor side yoke 1" 3/8 Z6)

COMMAND GROUP

ISOBUS control unit compliant with ISO standard ISO 11783

2 manual valves for operation and cleaning

Speed sensor on the tractor wheel

Pressure sensor

Flowmeter

Differential pressure gauge

START BOOM

Painted bar in cataphoresis and powders

Hydraulic lifting 39.37 in.

Open/close arms in sequence, right/left independent

Mechanical self-levelling with automatic blockage system

Unijet without nozzles

3 pairs of quick couplings required on the tractor

WORK U BOOM

Painted bar in cataphoresis and powders

Hydraulic lifting 39.37 in., double hydropneumatic shock absorber

Simultaneous opening and closing of the arms

Simultaneous opening and closing of the tips

Mechanical self-levelling with automatic blockage system

Sliding protections

Trijet without nozzles

3 pairs of quick couplings required on the tractor