Folding frame multispeed power harrow

TORO SUPER ISOTRONIC, the new top-of-the-range power harrow with folding frame and ISOBUS communication protocol, is the latest innovation from MASCHIO GASPARDO. Designed to meet the needs of the new generations of high-power tractors, it is the evolution of the TORO model to which many mechanical, structural and electronic innovations have been added, making it a unique piece of equipment on the market. Available with working widths between 5 and 7 metres, TORO ISOTRONIC can be combined with tractors of up to 400 HP.

TORO SUPER ISOTRONIC is the first power harrow to use ISOBUS technology. All the working parameters can be displayed through the ISOBUS terminal on the tractor: this simplifies the use of the equipment for the operator and optimises the life cycle of the harrow. It is possible to export the work data for diagnosis or processing in order to increase the efficiency of harrow use, search for anomalies and remotely supervise the work cycles. A series of sensors distributed on the machine allow constant monitoring of the main functions for full control of the equipment's operation, the power absorbed, the temperature of the oil in the gearboxes, the rotation speed of the rotors, the slip of the cardan PTO shafts, the actual working depth, the misalignment of the rollers, the correct positioning of the cardan PTO shafts joints when closing, the hours and hectares worked. In addition, an innovative solution based on two new patents allows a load cell to monitor the power absorbed to increase efficiency during work.

The structure remains the consolidated one of the TORO model, which represents the peculiar characteristics of the MASCHIO GASPARDO power harrows: double skin frame (6 mm inside and 5 mm outside), air cooling device of the central gearboxes, lateral camshafts, sturdier knife-holder shafts and thicker knives that hook onto knife-holders that are cast in a single block. The RAPID knife release and hydrostatic upward and downward floating system complete the standard equipment of high-level machines.

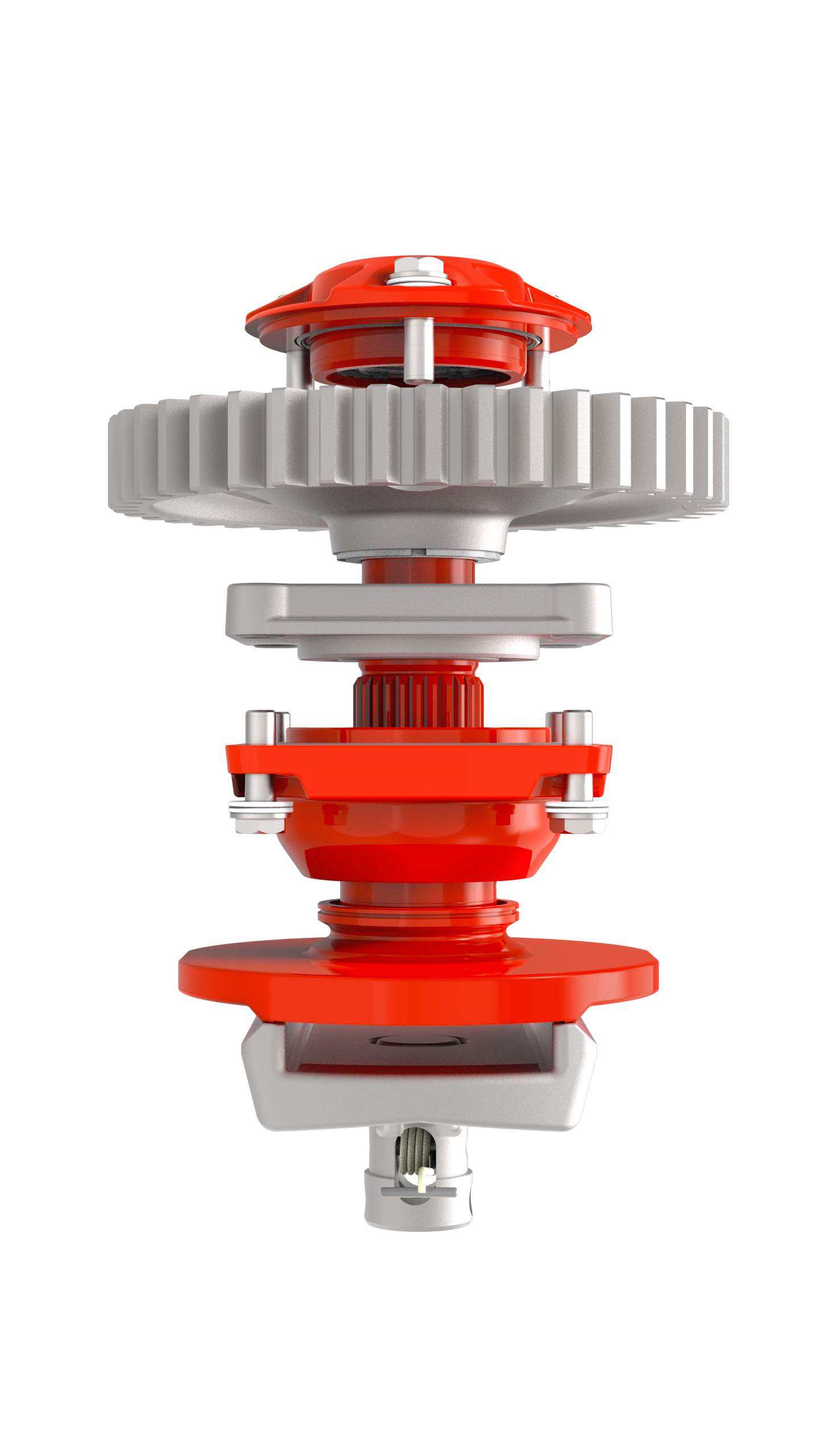

The innovations do not only concern the electronics, but also the mechanics. Thanks to patented technical and structural solutions (4 new patents), maximum robustness and excellent power absorption management are guaranteed.

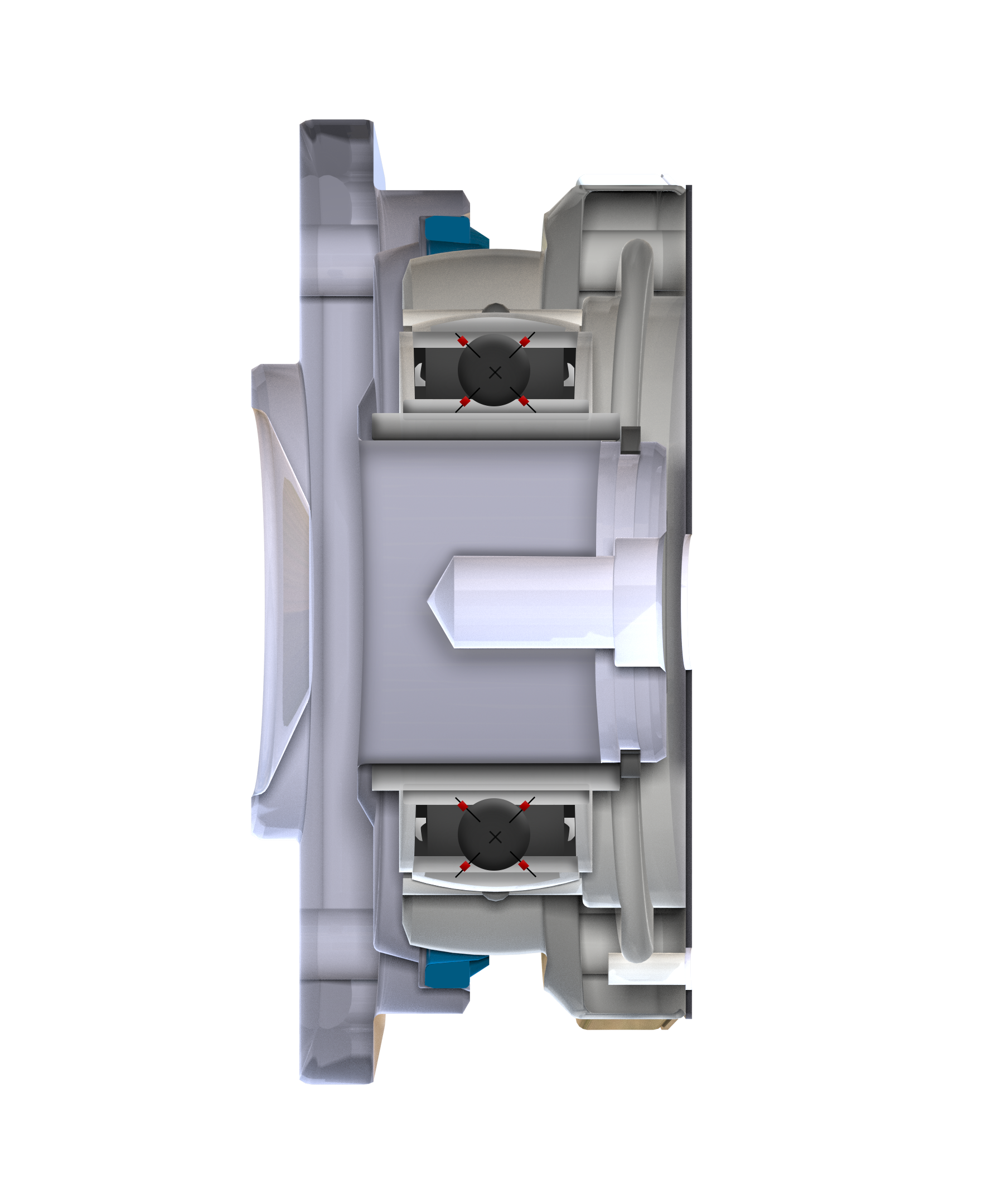

New features include the introduction of new bearings for the roller range called " Blindato", which protect the equipment from any type of contamination and allow an increase in the consistency of work quality in the field regardless of ground conditions.

The leveling bar is now higher and closer to the knives to improve soil crumbling.

A new oil recirculation system has also been designed that uses a tank inside tthe three point hitc, driven by a gear pump. The benefits are many: lower operating temperatures of the central gearbox, less degradation of the oil properties, with consequent lower risk of downtime and higher productivity. TORO ISOTRONIC has been further strengthened with 2 additional hinges on the wings.

The side cam PTO shafts are now protected by durable sheet metal covers which eliminate the problem of deterioration of the plastic protections, guaranteeing greater safety.

TORO SUPER ISOTRONIC is innovative also in its design. New and totally unprecedented are the rear clearance table with LED lights, the rear roller casings, the side cardan shafts, the yoke and the gearboxes. The design also has a functional purpose, protecting the most exposed parts, evaluating the overall dimensions and increasing the efficiency of the parts.

TORO SUPER ISOTRONIC can be combined with the CENTAURO cereal seed drill. This combined setup offers major advantages, primarily improving operational efficiency by allowing primary/secondary soil preparation and seeding in a single pass. With the new hydraulic seed bar exclusion kit, the soil can be worked with the seed bar tilted upward.

Why choose TORO ISOTRONIC

TORO SUPER ISOTRONIC makes it possible to know and modify all the working parameters in real time to save time, improve field performance and reduce costs. It is possible to export the working data for diagnosis or processing in order to increase efficiency.

| Measure | Working width (min) | Transport width | Roller | Ø roller | COMBI | No. of tines | Power required HP | Power required KW | Weight |

|---|---|---|---|---|---|---|---|---|---|

| 5000 | 16.4 ft | 7.87 ft | Cage | 216.54 in | Optional | 40 | 160-400 hp | 119-298 kW | 9,038.86 lb |

| 5000 | 16.4 ft | 7.87 ft | Packer | 196.85 in | Optional | 40 | 160-400 hp | 119-298 kW | 10,354.57 lb |

| 5000 | 16.4 ft | 7.87 ft | Packer | 216.54 in | Optional | 40 | 160-400 hp | 119-298 kW | 8,818.4 lb |

| 5000 | 16.4 ft | 7.87 ft | Combipacker 125 | 196.85 in | Optional | 40 | 160-400 hp | 119-298 kW | 9,038.86 lb |

| 6000 | 19.68 ft | 7.87 ft | Cage | 216.54 in | Optional | 48 | 180-400 hp | 134-298 kW | 9,920.7 lb |

| 6000 | 19.68 ft | 7.87 ft | Packer | 196.85 in | Optional | 48 | 180-400 hp | 134-298 kW | 9,667.17 lb |

| 6000 | 19.68 ft | 7.87 ft | Packer | 216.54 in | Optional | 48 | 180-400 hp | 134-298 kW | 9,964.79 lb |

| 6000 | 19.68 ft | 7.87 ft | Combipacker 125 | 196.85 in | Optional | 48 | 180-400 hp | 134-298 kW | 10,207.3 lb |

| 7000 | 22.97 ft | 7.87 ft | Cage | 216.54 in | no | 56 | 249-400 hp | 186-298 kW | 11,023 lb |

| 7000 | 22.97 ft | 7.87 ft | Packer | 196.85 in | no | 56 | 249-400 hp | 186-298 kW | 11,023 lb |

| 7000 | 22.97 ft | 7.87 ft | Packer | 216.54 in | no | 56 | 249-400 hp | 186-298 kW | 10,780.49 lb |

| 7000 | 22.97 ft | 7.87 ft | Combipacker 125 | 196.85 in | no | 56 | 249-400 hp | 186-298 kW | 11,155.28 lb |

TRACTOR CONNECTION

3 point hitch cat. III^ and IV^ with reduction bushings for cat. IV^

TRANSMISSION

PTO direct shaft

Side cam-shafts

Double greasers in side shafts

Rear PTO

Cooling fans for side gearboxes

Cooling system for central gearbox

Steel protections for side shafts

Heavy duty rotor support bearings "POWER HUB"

Quick disassembly of the central drive shaft protection hood

Side multi-speed gearboxes

Velocità rotore - PTO 1000 rpm:

Z19 PTO - Z26 pinion = 353 rpm

REAR ROLLER

Rear roller with hydraulic adjustment

Levelling bar with hydraulic adjustment

Heavy duty roller bearings "BLINDATO"

Protective carter on the rollers

FRAME

Side dampened protections

«CE» protections

Hydraulic floating system

Safety manual locks for transportation

Central eradicator

Reinforced anti-jam wedges "PLUS"

Rear led lights "VISION"

TEETH/BLADES

Tooth thickness 0.63 in.

Quick tine release

The machine can be combined with a seed drill