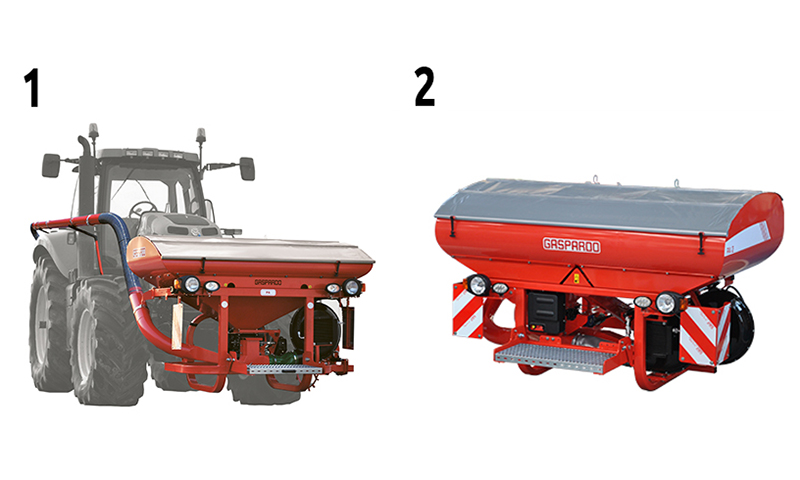

Frontal hopper for the distribution of a single product (seed or fertilizer)

The front PA1 hopper is an application designed for the distribution of seeds or fertilizer. Available with a capacity of 1,100 l, it works in conjunction with precision planters from MTR range, from the seed drill range, both in-line and combined, and from the row crop cultivator range.

The front position in front of the tractor guarantees an excellent balance, especially with very bulky rear implements such as precision planters and row crop cultivators up to 12 rows. Furthermore, the particular design with sloping profile does not limit front visibility even when travelling on the road, which is absolutely safe also thanks to the front lights.

The ISOTRONIC electric transmission and ISOBUS communication system, allows digital control of the front hopper and the use of all Precision Farming functions.

The centralized volumetric metering unit allows the use of different metering rollers both according to the type of product and the dose.

The transport of the product is compulsorily pneumatic by means of a hydraulic blower, equipped with a radiator cooling system. The blower can be operated by the tractor's hydraulic system or independently via the tractor's power take-off.

The PA1 PACKER version uses a support roller consisting of 4 tires with a very generous tread that considerably reduces compaction.

| Hopper capacity | Transport width | N. of dosing rollers | Transmission | Version | Fan drive | PTO rpm | Hitch | Weight |

|---|---|---|---|---|---|---|---|---|

| 290.62 gal | 7.22 ft | 1 | Electric | without packer roller | Hydraulic dependent | - | 3 point cat. II^ | 1,278.67 lb |

| 290.62 gal | 7.22 ft | 1 | Electric | without packer roller | Hydraulic independent | 1000 std | 3 point cat. II^ | 1,455.04 lb |

| 290.62 gal | 7.22 ft | 1 | Electric | with packer roller | Hydraulic dependent | - | 3 point cat. II^ | 1,763.68 lb |

| 290.62 gal | 7.22 ft | 1 | Electric | with packer roller | Hydraulic independent | 1000 std | 3 point cat. II^ | 2,028.23 lb |

1 centralized volumetric doser

F25-125, G1000 and N500 metering rollers for seed, G1002 for fertilizer

ISOBUS GENIUS MASTER system (ISO 11783)

ISOBUS cable female - female 6.6 feet

ISOBUS cable male - female 24.6 feet

GPS speed sensor

Pneumatic distribution with hydraulic fan drive: dependent through tractor hydrualic distribution; independent PTO 1000 rpm

Gearbox oil cooler system with radiator

Electronic balance in scale

16.40 ft of rigid tube for conveying product

32.81 ft of spiralled tube

Inspection footboard

Inner tank deflector for fertilizer support

Slingshot for distributor exclusion

Inside hopper grid

light kit

Warning boards