Now, a word from the MASCHIO GASPARDO agronomist

MASCHIO GASPARDO continuously develops solutions to support farmers in maximizing yields, while at the same time reducing environmental impact, optimizing the use of natural resources, and ensuring compliance with regulatory standards.

Protecting crops from diseases and pathogens must go hand in hand with optimizing the use of plant protection products. In addition to synthetic pesticides, it is important to consider alternative solutions such as mycoparasites and resistance inducers, thereby promoting more sustainable agriculture.

In this context of sustainable agriculture, direct seeding and minimum tillage are becoming increasingly widespread, allowing significant energy savings and, consequently, reductions in air pollution. However, these practices can also lead to greater weed proliferation, making the careful use of crop protection products increasingly essential.

Although mechanical tillage can be a valuable ally in weed control, for certain types of plants with stolons, rhizomes, tubers, or sprouting roots, this practice may prove insufficient. In some cases, mechanical tillage might even encourage the spread of these unwanted species.

Finally, the use of sprayers also enables foliar fertilization through the use of specific nozzles—a practice that can improve the effectiveness and distribution of micro- and macronutrients, especially under challenging conditions that hinder nutrient absorption, such as unfavorable PH levels, temperature, or drought.

Minimal overlaps with SPRAY-IQ

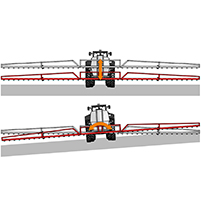

SPRAY IQ is the ideal solution for farmers looking to maximize the benefits of ultra-precise nozzle management in irregular fields and overlap zones, thanks to its automatic 50 cm section control.

The SPRAY-IQ system automatically manages the opening and closing of each nozzle, ensuring full control and precise application even at higher driving speeds, while minimizing overlaps. Operating with sections as small as 50 cm, SPRAY-IQ guarantees that crops consistently receive the best possible treatment.

Key benefits:

- Potential savings of up to 80% on chemical products in wedge-shaped fields due to reduced overlap;

- Reduction of crop damage caused by overdosing.

- Minimize environmental impact for a more sustainable approach.

MASCHIO GASPARDO 'VENTO': saving you time and money in every operation.

Weather conditions influence virtually every farming activity, and wind in particular can force a farmer to interrupt or postpone treatments due to drift.

The 'VENTO' air sleeve system uses an adjustable air curtain to channel the sprayed product, significantly reducing drift. The result is virtually no dispersion of plant protection products or contamination of adjacent areas. Efficient drift control also ensures a wider operational window, higher application speeds, and fewer stops for refilling—leading to increased productivity for the operator.

Using VENTO also ensures better penetration and coverage compared to conventional applications—an essential advantage in crops with dense vegetation. This results in real savings for the farmer, with at least a 50% reduction in water usage and up to 30% savings on crop protection products.

The VENTO system is equipped with an independent hydraulic pump that powers a high-performance Ø800 mm fan, continuously adjustable up to a maximum airflow of 40,000 m³/h and a maximum air speed of 32 m/s.

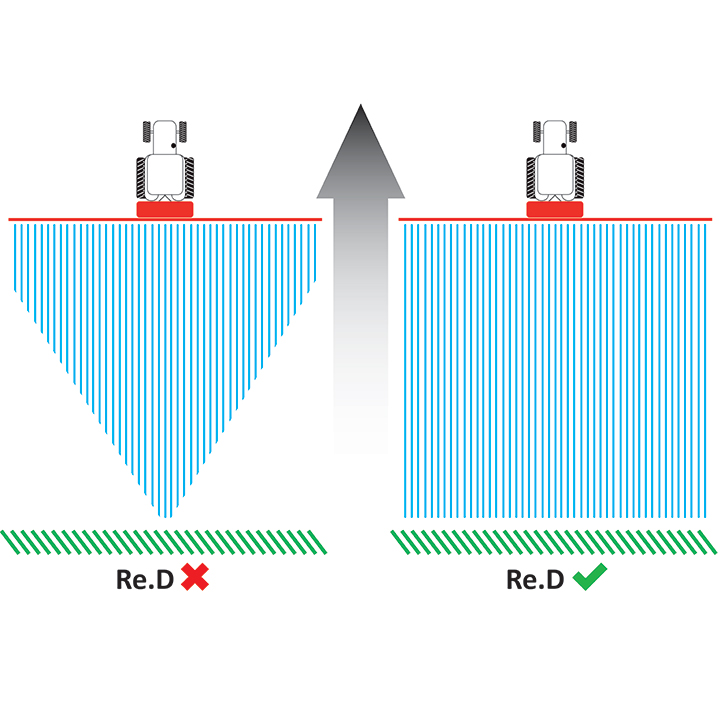

Get the most out of your crop protection products with 'Re.D'

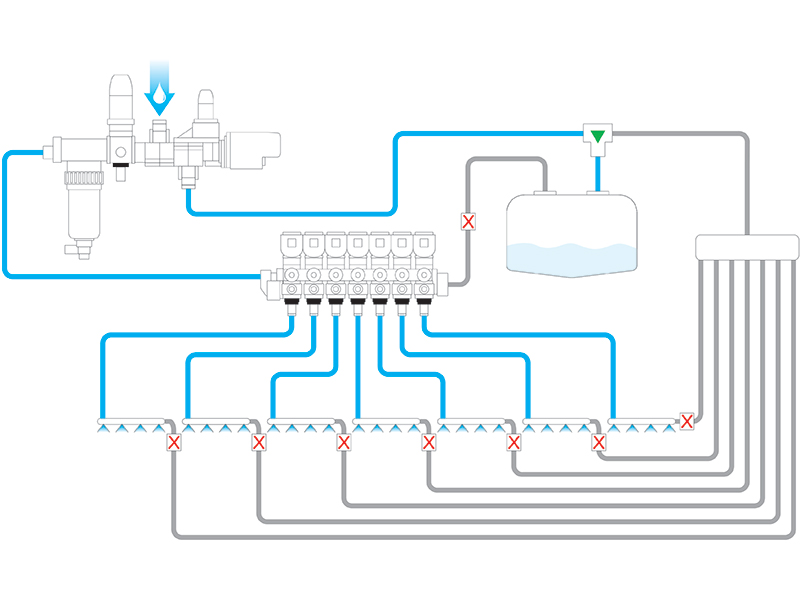

The Re.D (Recirculation Dynamics) pressurized recirculation system gives farmers the confidence to start treatments knowing that the product is already evenly distributed throughout all sections. When spraying operations begin, the entire circuit is pressurized, meaning that the boom sections are always ready for use across the full working width. As a result, there are no delays at headlands, preventing the formation of untreated areas."

Furthermore, whenever the sections are closed, the mixture continues to circulate thanks to the pressurized recirculation system. This feature of the Re.D system helps reduce mixture sedimentation in the pipes, minimizing the volume of undiluted product left in the sprayer at the end of the job. This not only preserves application effectiveness throughout the entire operation, but also improves end-of-task efficiency—enhancing overall process performance and increasing treatment quality.

E-Panel: total control with maximum comfort

MASCHIO GASPARDO E-PANEL, available for ISOTRONIC sprayers, controls the most important functions of the hydraulic system through an electric valve system, which can be managed either from the tractor cab or directly on the machine via a dedicated monitor. E-PANEL allows the operator to work with complete peace of mind, minimizing the risk of error.

The functions available to the operator are:

- Automatic fill stop;

- Proportional agitation control: agitation intensity is adjusted based on the fill level, gradually decreasing until it is completely stopped to prevent foam formation;

- Automatic rinsing of the hydraulic circuit, both full and partial.;

- Filter cleaning even with a full tank;

- Work light management;

- Service operations interface.

Maximum stability and precision with DISTANCE CONTROL and DISTANCE CONTROL PRO

Boom stability is a crucial factor in spraying operations, as it ensures proper application of crop protection products, reduces operator fatigue, and extends the overall lifespan of the sprayer.

DISTANCE CONTROL It is a fully automatic control system that adjusts the boom’s height and tilt using ultrasonic sensors, which monitor and correct movements through on/off valves..

DISTANCE CONTROL PRO It also allows active and independent control of the boom wings (variable geometry). This means they can be tilted either upward or downward independently of each other using hydraulic cylinders and proportional valves.

The advantage of these systems is their ability to actively reduce any negative effects on spraying quality caused by uneven terrain or other driving-related factors. As a result, the boom can better follow the topography of the land—even highly irregular surfaces—while consistently maintaining an optimal distance from the target surface across the entire working width. In addition, the use of... DISTANCE CONTROL helps reduce the risk of drift, delivering direct benefits for both the farmer and the environment.