Novelty - TORO ISOTRONIC - United Kingdom

Novelty - TORO ISOTRONIC

TORO ISOTRONIC

Complete management of performance

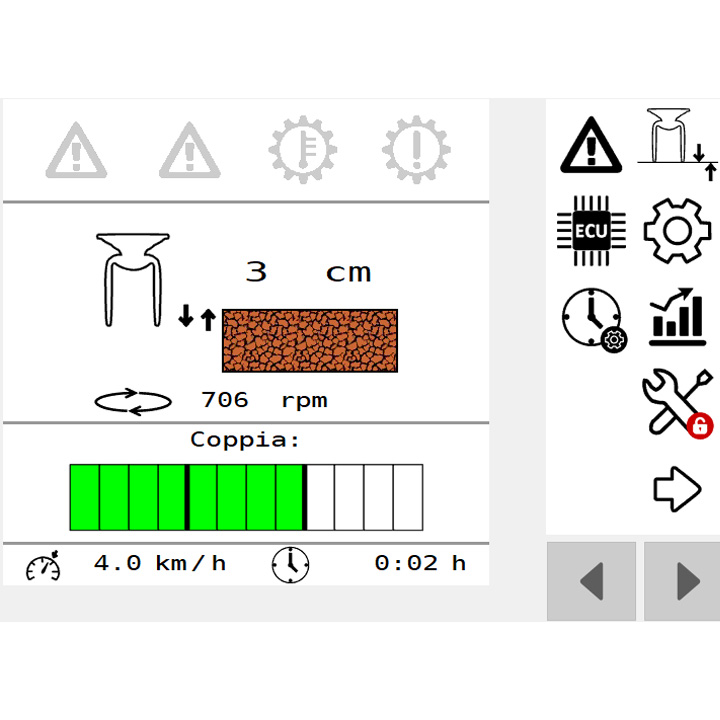

A series of sensors distributed on the power harrow allow the user to constantly monitor the main functions. All working parameters can be managed through the ISOBUS terminal installed on tractor.

It is possible to check the power absorbed, the oil temperature in the gearboxes, the rotation speed of the rotors, the cardan slippage, the real working depth, the misalignment of the rollers, the correct alignment of the cardan joints when closing ("PTO shafts protection") and the hours worked.

This simplifies the use of the machine for the operator and optimises the life cycle of the power harrow thanks to on time performance checks.

Increased robustness

The reinforced transmission body made of high strength steel is constituted by a double case structure: with a thickness of the inner sheet of 6 mm and 5 mm of the external one, greater rigidity and robustness are granted. These features allow to obtain high performances in a variety of conditions.

New bearing “BLINDATO” for the rollers range

From a mechanical point of view, TORO ISOTRONIC mounts new roller bearings of the "ARMORED" type with an innovative polyurethane scraper ring that further protects from any contamination. This mechanical improvement allows greater protection of the bearing, extends the life of the machine and reduces possible downtime.

Perfect for Agriculture 4.0

In TORO ISOTRONIC all the working parameters can be managed comfortably from the ISOBUS terminal on the tractor in a simple and intuitive way.